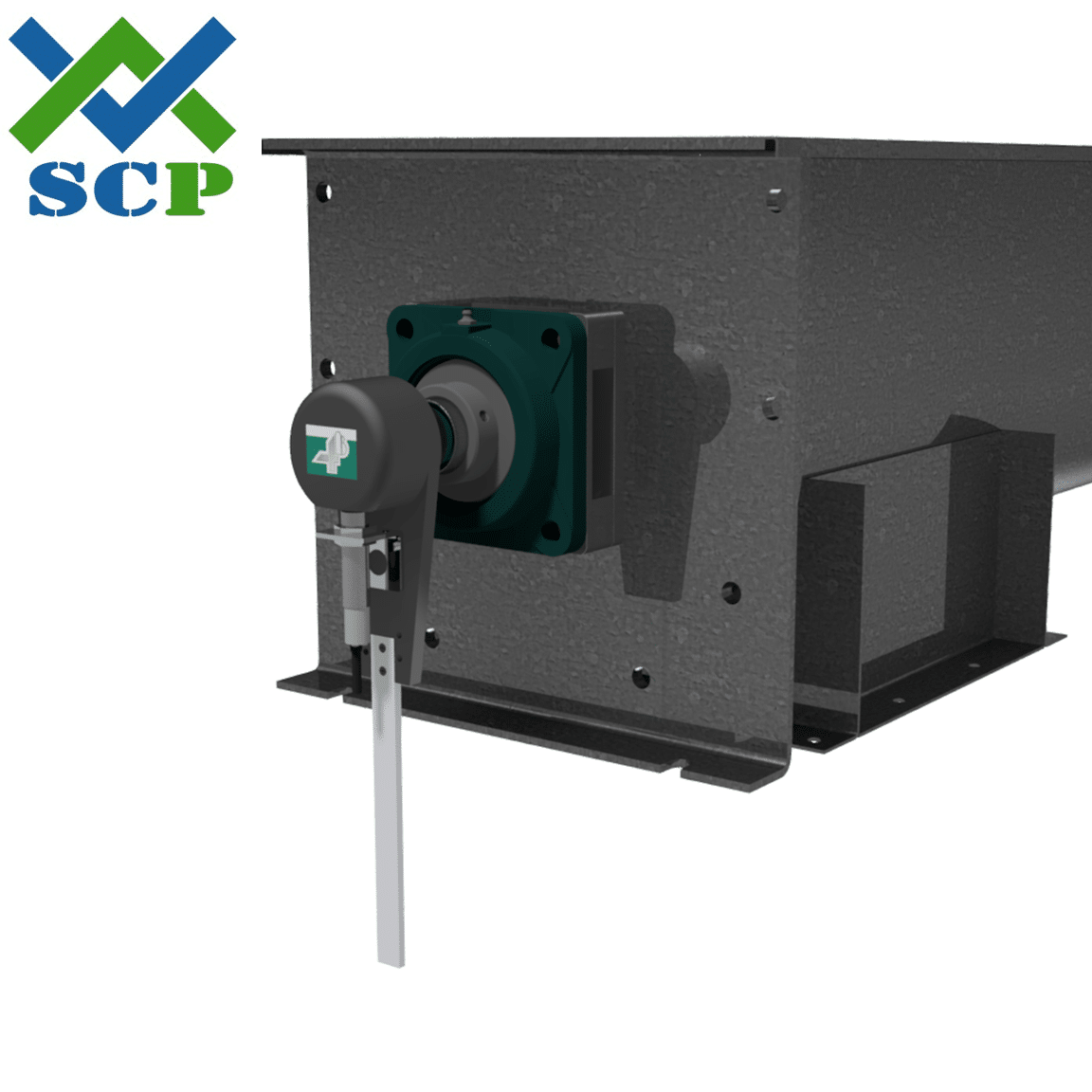

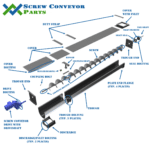

The 4B M100 Stop Switch with whirligig and magnetic base are a truly plug and play solution for monitoring your screw conveyor. The assembly attaches directly to the tail shaft and is held in place with the included magnetic adapter. The intrinsic switch has a single set point, which signals when the screw has stopped rotating. Ease of use and mounting make this an ideal solution for keeping a remote eye on your screw conveyor.

| SPECIFICATIONS | |

| Supply – | 24 to 240 Volts AC/DC |

| Switching Capacity – | 200 mA Maximum |

| Saturation Voltage – | 8 Volts Maximum (Output On) |

| Leakage Current – | 1.6 mA Maximum (Output Off) |

| Operating Temperature – | -13°F (-25°C) to +158°F (+70°C) |

| Relative Humidity – | 90% RH |

| Sensing Range – | Ferrous Target – 5/16 Inch (8 mm) Maximum Non-Ferrous Target – 3/16 Inch (5 mm) Maximum |

| Enclosure – | Nylon – ISO Threaded 18 mm by 1 mm Pitch |

| Cable – | 6 ft. (2 m), 2 Conductor |

| Output State – | Normally Closed (Volt Drop 8 Volts Max.) Above Minimum Input Speed Normally Open (Leakage Current 1.6 mA Max.) at Stopped Motion |

| Input Pulse Range – | 20 to 2,000 PPM Maximum |

| Start Up Delay – | 4 Seconds |

| Trip Point – | Stopped Motion if No Input Received for a Period of 4 Seconds |

| LED Indicators (2) – | Red (Input) = Target Sensed Green (Output) = Closed Circuit |

| Protection – | IP67 |

| Approvals – | CSA Class II Division 1 Groups E, F and G (USA & Canada) ATEX & CE Versions Available (Europe) |