Frequently Asked Questions for Screw Conveyor Parts

Welcome to Screw Conveyor Parts, LLC. We are here to help make your screw conveyor parts and component buying experience informed and as efficient as possible. We strive to be the web’s number one resource on screw conveyors and screw feeders. Every week, we get hundreds of questions from customers just like you. These questions are the basis for the content on our site. We have catalogs, technical articles, selection guides, industry resources and even a fair amount of technical expertise to help answer your questions. Below are some questions from visitors just like you. If you don’t see an answer to your questions below or in our articles section, send us an email at [email protected] or fill out the form below. Thank you for browsing and we look forward to serving all your screw conveyor needs.

Frequently Asked Questions

Can I buy screw conveyor parts and components from screw conveyor manufacturers?

There are several manufacturers of screw conveyor parts in the United States. (See more about manufacturers HERE) Most of these manufacturers put a lot of money into getting their name out there and trying to distinguish themselves as the best, cheapest, or whatever. The truth is, when it comes to screw conveyor parts and components all the manufacturers are making the same parts. (See more HERE) Where each manufacturer distinguishes itself is in customer service and technical expertise.

In addition to each manufacturer making the same parts, none of the major screw conveyor manufacturers will sell parts and components directly to a customer. They all sell through a distributor. So, when you see that great add for trough ends, hanger bearings and replacement screws from a screw conveyor manufacturer, keep in mind they are going to direct you to a distributor to buy, which is why you are better off to buy directly from www.screwconveyorparts.com.

Can you help me size my screw conveyor?

Yes we can! Send us the information on you application to [email protected] and we will help out. You can also view our article on sizing a screw conveyor or send us what you need and we will help. Below are a few of the items we need to help size your screw conveyor.

- Material being conveyed?

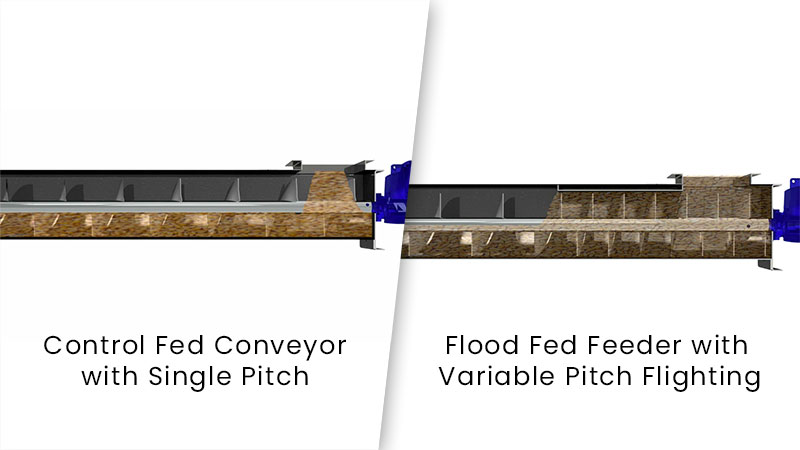

- Is the inlet control or flood fed?

- Desired rate? (CFH or PPH)

- Length?

- Incline?

Is Screw Conveyor Parts, LLC a screw conveyor manufacturer?

We are an independent screw conveyor company designing and selling screw conveyors, feeders, systems and parts. We use a blended approach where we manufacture, modify and/or purchase our components to offer the best selection and price possible.

Do you have a customer service hotline?

Yes.

You can email us at [email protected] or call at 682-231-1228. We would love to help you with your screw conveyor needs.

Do you sell 3“ diameter screws?

For most screw conveyor manufacturers, 6″ diameter is the smallest cost effective size that can be manufactured. Many traditional screw conveyor manufacturers can make 4″ screw conveyors, but anything below that usually requires special tooling. In addition, CEMA does not standardize below 6″ screws. Because these smaller screws tend to be in specialty applications, and therefore cannot be standardized, we do not offer them. There are a few companies that do make these smaller screws. Auger fab has done a good job in the past and would be a good source to look at. Their website is https://www.all-fill.com/auger-fabrication/.

Do you offer a plastic screw 30“ dia x 8′ long for a food application?

That is a tough one. We are not sure of anyone who can make a 1-piece plastic screw that big.

The best we have seen are plastic flights that slide on the shaft, but we don’t think anyone makes them to 30″dia.

You would have to have a custom extruder company help and unfortunately we do not currently work with one. Sorry we can’t be of more assistance.

Is my dust collector screw a conveyor or feeder?

If you have a rotary airlock at the inlet of the screw conveyor, the screw conveyor is control fed and the rotary airlock is the feeder. If the airlock is at the discharge of the screw conveyor and the screw conveyor runs while the dust collector is on, the conveyor is control fed. If the screw conveyor only comes on when the dust collector hopper is full, the screw conveyor is flood fed and should be considered a screw feeder.

What is the difference between a screw conveyor and a screw feeder?

A screw conveyor is considered a screw feeder when the inlet is flood fed like when it is under a hopper, bin or silo. A screw conveyor has a control fed inlet coming from a rotary feeder, screener, screw conveyor, belt conveyor, etc.

Can I run a 4" screw conveyor at 350 RPM like a flexible auger?

The flex auger is in a housing and when it runs at 350RPM it can essentially bounce off the inside of the tube to stay centered. A shafted conveyor cannot and has to be balanced for high speeds. The main disadvantage of a flex auger is they wear out pretty fast compared to a shafted auger and tend to cost more. The advantage is the are compact and can run at steep angles very easily.

What is a Shaftless Screw Conveyor?

A shaftless conveyor is a mechanical conveyor using a spiral with no center pipe or shaft. The spiral is designed to convey the bulk material and handle the torque from the screw conveyor drive without distortion or failure.

What is a feeder shroud?

The feeder shroud turns the open U shape of a screw conveyor into a round tubular shape. The only place the material has to go is through the screw. Without it the material at the flooded inlet would flow past the inlet and over the screw and controlling the rate would be impossible.

Shop for feeder shrouds HERE.

Should my Screw Conveyor Drive go at the Inlet or Discharge?

Ideally, the screw conveyor drive is at the discharge end. This allows the screw to 1. operate under tension, reducing stress and wear and 2. protect the drive from contamination caused by product running down the shaft if at the bottom of an inclined screw conveyor.

Shop for screw conveyor drives HERE.

What is the difference between a screw conveyor foot and saddle?

A screw conveyor foot is designed to bolted to the trough end flange to provide support for the screw conveyor. A screw conveyor saddle is designed to be welded anywhere along the bottom of the trough to provide support for the screw conveyor.

Shop for screw conveyor feet and saddles HERE.

What is a shroud for steep inclines?

The shroud encapsulates the screw, turning the open U shape into a round shape. The shroud runs the full length of the screw. For steep inclines over 20 degrees the material can fall back over the top of the flights rendering the screw conveyor ineffective. The shroud prevents this fall back and allows for efficient and effect conveyance.

What Speed Should I Run my Screw Conveyor at?

Screw conveyors should run 40-60 RPM. Screw feeders should run 20-40 rpm.

Both these speed ranges offer good performance and long term reliability.

What comes with a screw conveyor kit?

The short answer is everything except the screw conveyor drive. We supply all the screw conveyor parts, hardware and gasketing. Every part is labeled with the PN and description.

Which end of the screw conveyor does my drive go on?

The screw conveyor drive should go on the discharge end to protect the shaft seal and to keep the screw in tension.