The simple answer is yes, in most cases screw conveyor parts from any manufacturer will fit in your screw conveyor.

The Conveyors Equipment Manufacturers Association (CEMA) has been publishing dimensional standards for a long time for u-trough, flared trough and screws. All North American manufacturers adhere to these standards. Where the buyer needs to be careful are in specialty applications like special trough and trough end sizes, special configurations, imported screw conveyors and non-traditional screw conveyor applications like screws welded and polished. The list below are some common screw conveyor parts to watch out for.

216 Hanger Bearings – CEMA created dimensional standards for the 216 hanger bearing in about 2012, but several of the manufacturers could not agree on the width of the hanger body bar. The article explains more.

Trough Ends – The flange pattern for u-trough trough ends is standardized per CEMA 300. What is not standardized is the projection of pedestal trough ends and other specialty trough ends. Various manufacturers use various lengths and this can affect the location of the outboard bearing.

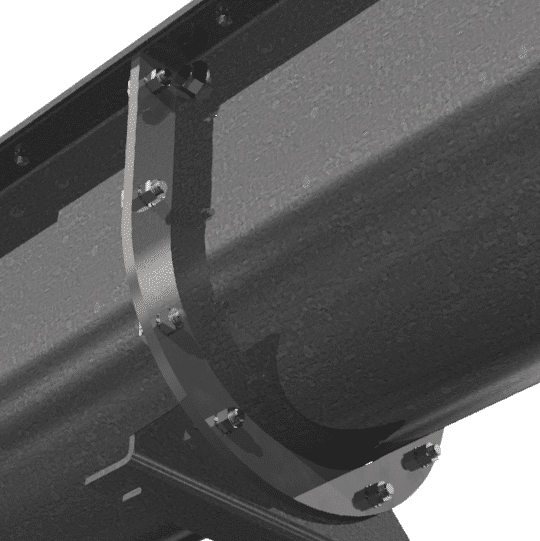

Tubular Troughs and Trough Ends – Most of the parts are compatible for tubular troughs and troughs ends between most manufacturers but there is a slight difference in the flange pattern between the various manufacturers, especially KWS and Martin (Click here for more information about manufacturers)

Rectangular Troughs and Trough Ends – CEMA does not have any published standards on these flange patterns

Shaft Sizes > 3 7/16″ – Coupling bolt patterns for larger shaft sizes have only recently been standardized by CEMA and some manufacturers are still not building to these standards.

Round Inlets and Discharges – CEMA does not have any published standards on these patterns. Most manufacturers follow their on tubular trough flange patterns.