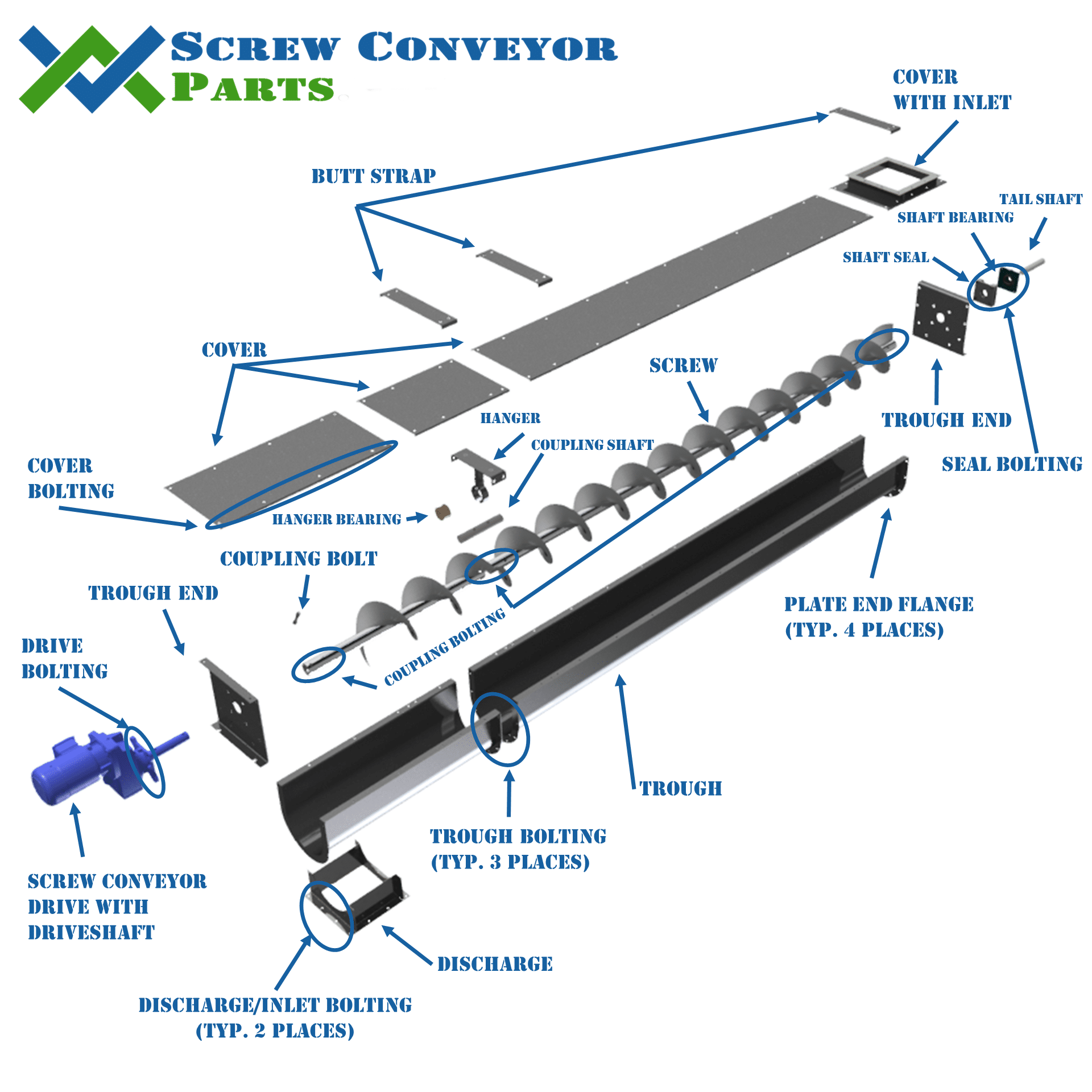

Interactive Screw Conveyor Diagram

Screw conveyors are a reliable and economical bulk material handling solution. With CEMA standardized parts, your screw conveyor can provide almost infinite service by replacing parts as they, or before they, wear out. Use this diagram to find the parts you need, learn more about them and buy them all on on place.

Screw Conveyor Components

Select a Component for More Information

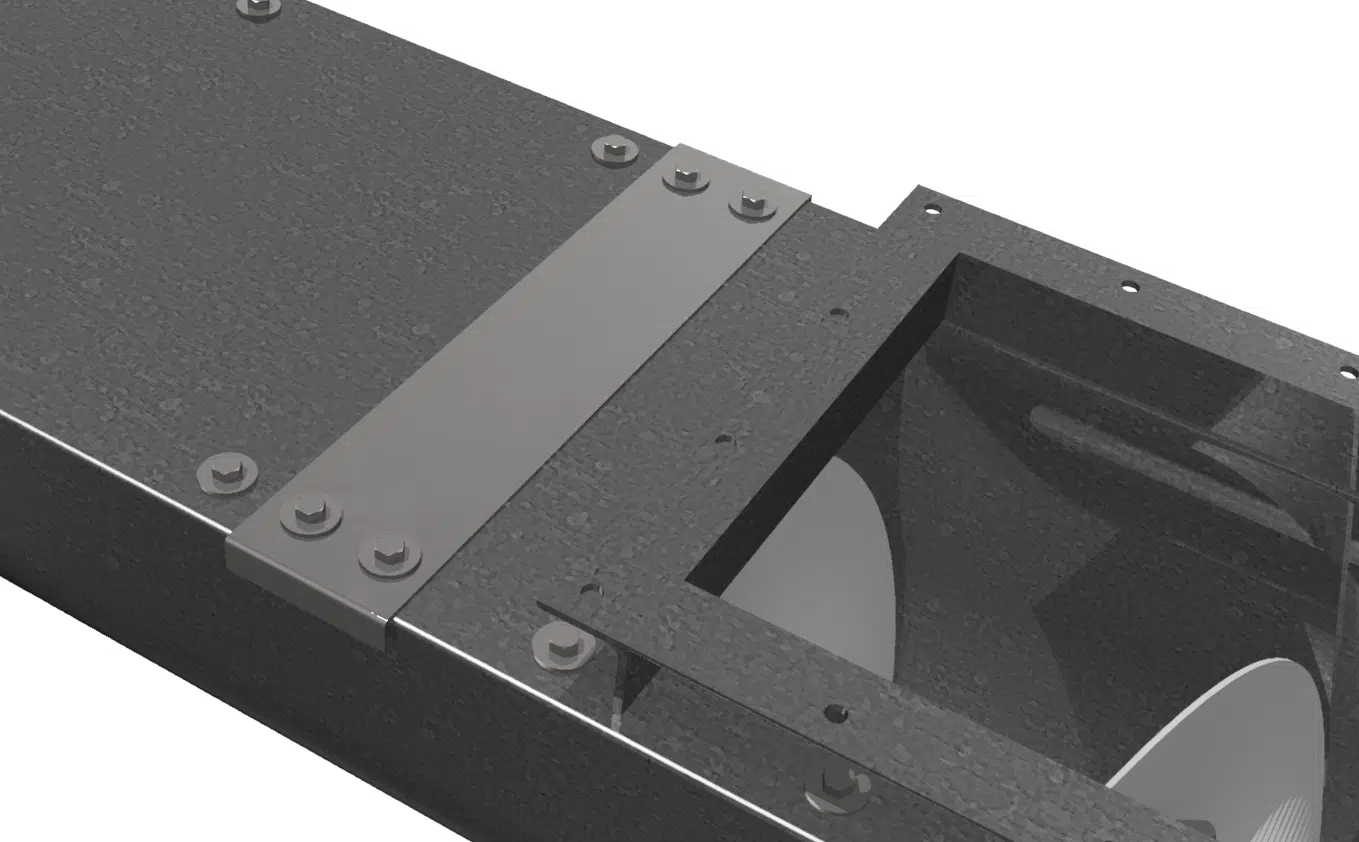

Buttstrap

The screw conveyor buttstrap is an integral part of the cover system. The buttstrap is used at each cover joint to minimize dusting and provide a weather tight seal. The buttstrap is specifically designed to accept the same gasketing as the trough flange for ease of assembly. SCP offers buttstraps for every screw conveyor size.

View ProductsDischarge/Inlet Bolting

The screw conveyor discharge and inlet bolting is used to attach adjacent screw coveyors together via the standardized flange pattern. When properly torqued these bolts offer abundent clamping force to keep these connections secure. SCP offers discharge and inlet bolting kits for all the standard screw conveyor diameters.

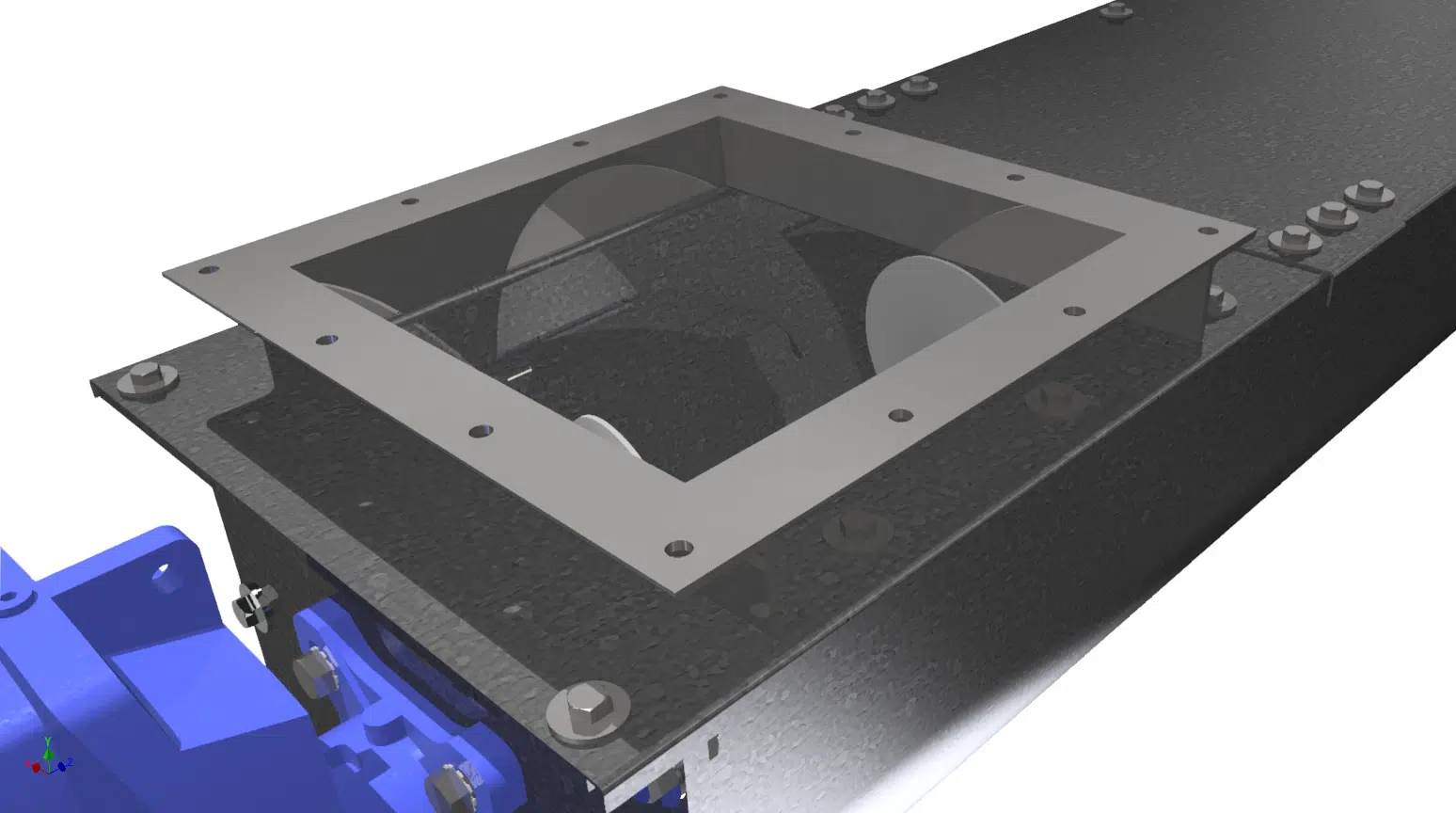

View ProductsDischarge

The screw conveyor discharge is pre-sized to maximize the cross-sectional area of the product exit. The discharge is standardized based on the screw diameter and matches the inlet pattern to allow bolting of consecutive screw conveyors together. SCP offers standard inlets for every screw conveyor diameter.

View ProductsTrough Bolting

The screw conveyor trough bolting is used to hold adjacent troughs to gether or troughs to trough ends via the plate end flanges. When properly torqued these bolts offer abundent clamping force to keep the troughs in place. SCP offers trough bolting kits for all the standard screw conveyor diameters.

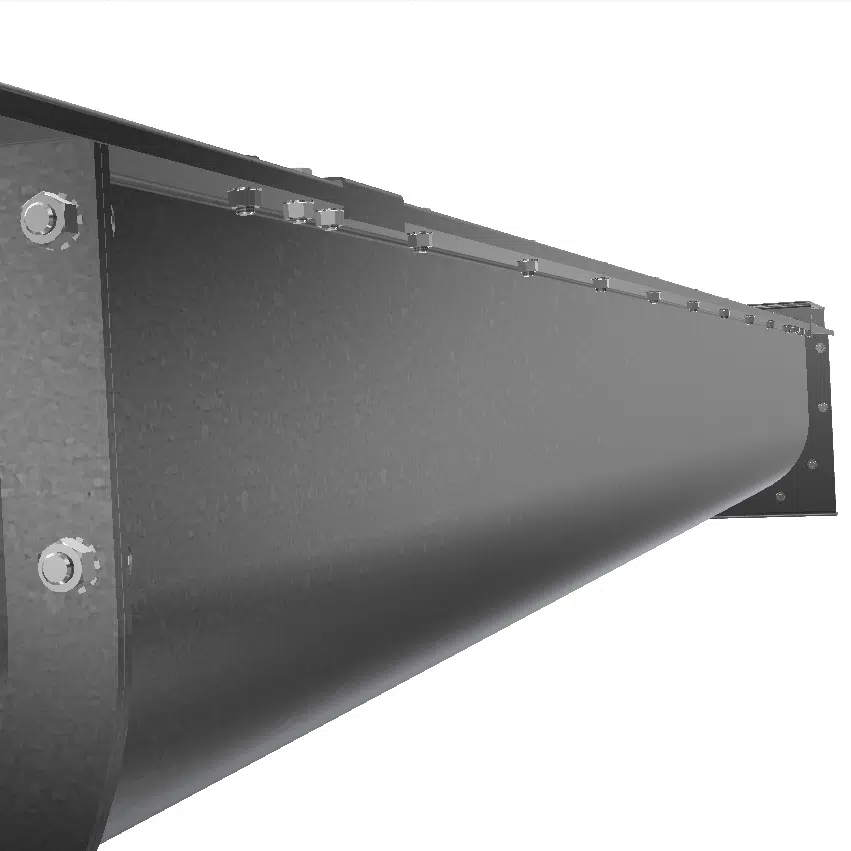

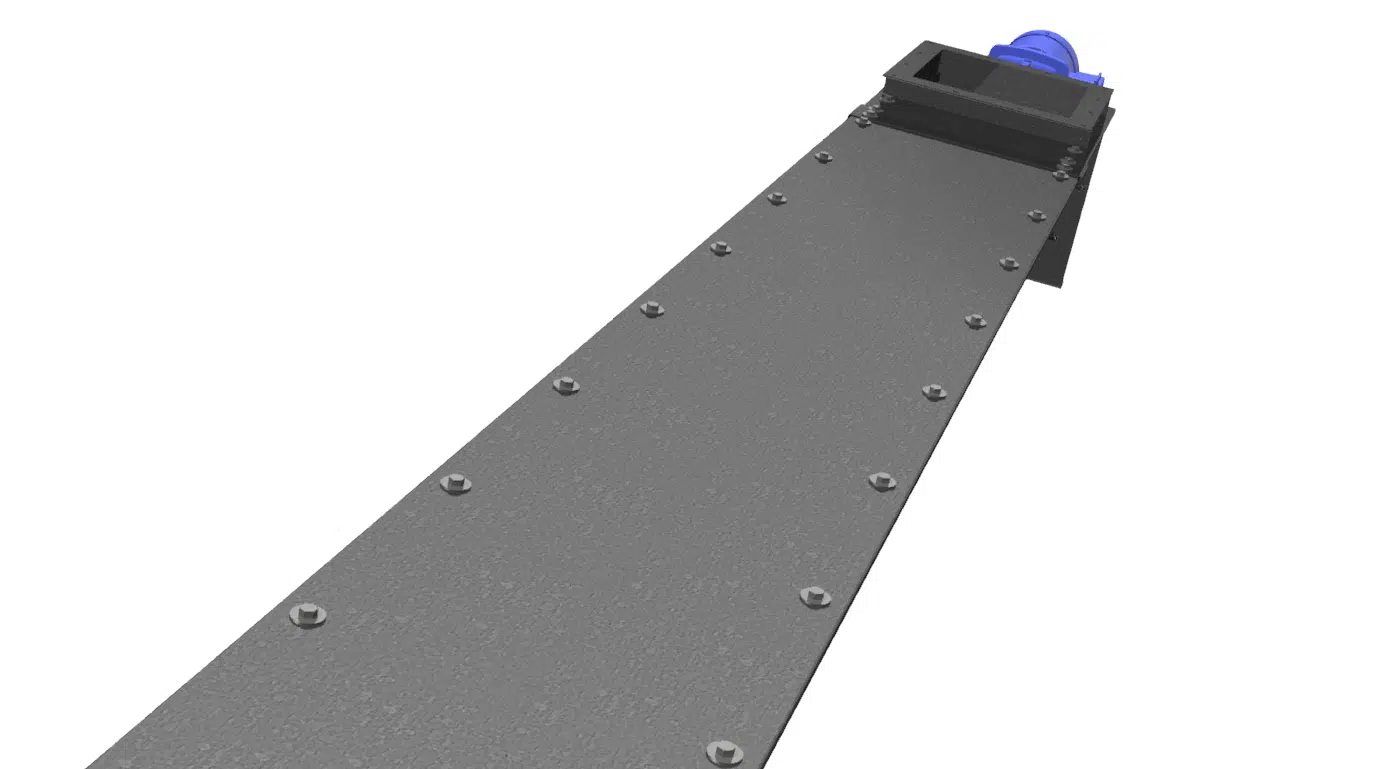

View ProductsTrough

The screw conveyor trough is the housing of the screw conveyor and is the main surface the productl moves on. The trough is made from plate steel and formed to the shape required The most common is the U shaped trough which allows for easy bolt of covers with the integrated cover flange. SCP offers troughs in all the standard screw conveyor diameters.

View ProductsPlate End Flange

The screw conveyor plate end flange is used to connect the trough to adjacent troughs or trough ends. CNC burned from plate steel with the CEMA std trough flange pattern plate end flanges allow for easy and reliable bolting. The plate end flange can be purchased seperately for shortning troughs and is included at each end of standard troughs. SCP offers plate end flanges for each standard screw conveyor diameter.

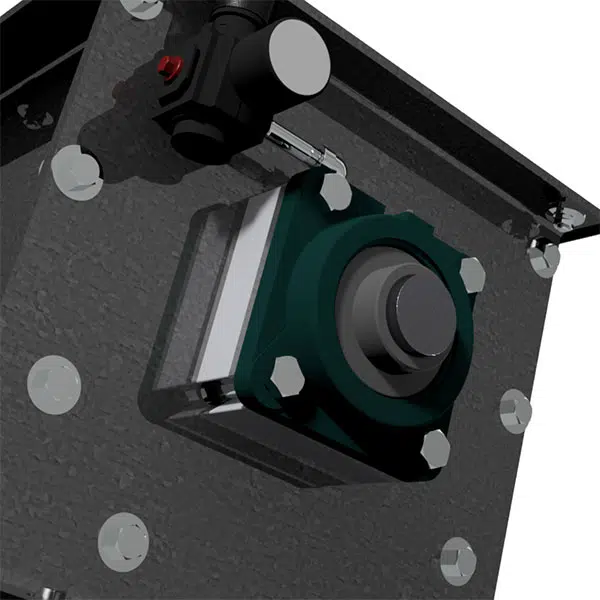

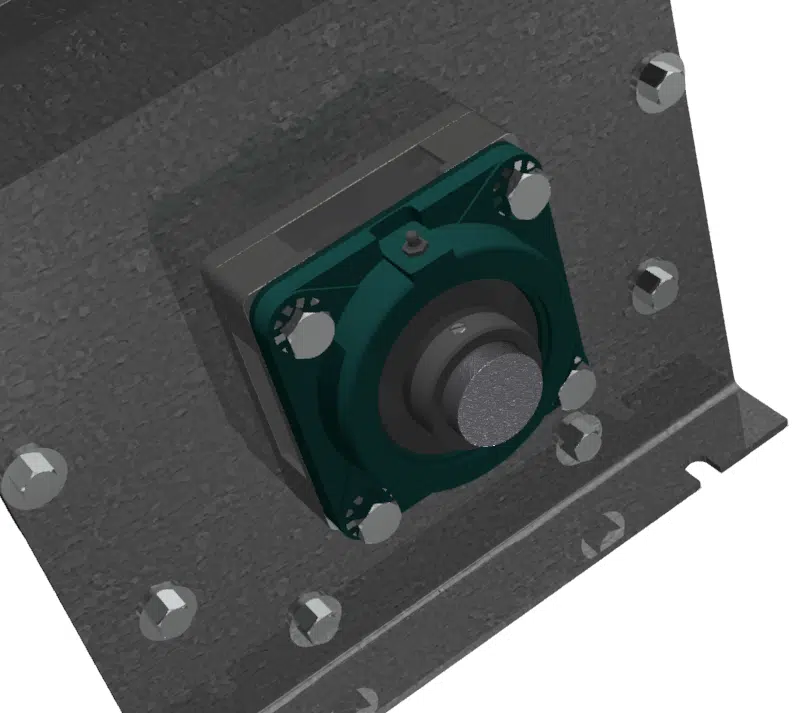

View ProductsSeal Bolting

Screw conveyor seal/tail bolting is used to hold the screw conveyor tail bearing and shaft seal to a standard trough end. The bolts go through both the trough end, shaft seal and tail bearing. When properly torqued, these bolts offer abundent clamping force to keep the screw conveyor tail shaft and seal secured. SCP offers drive bolting kits for all the standard shaft sizes.

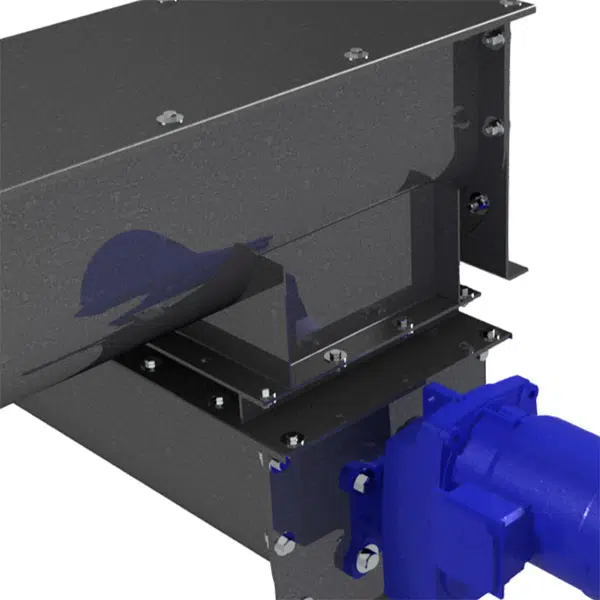

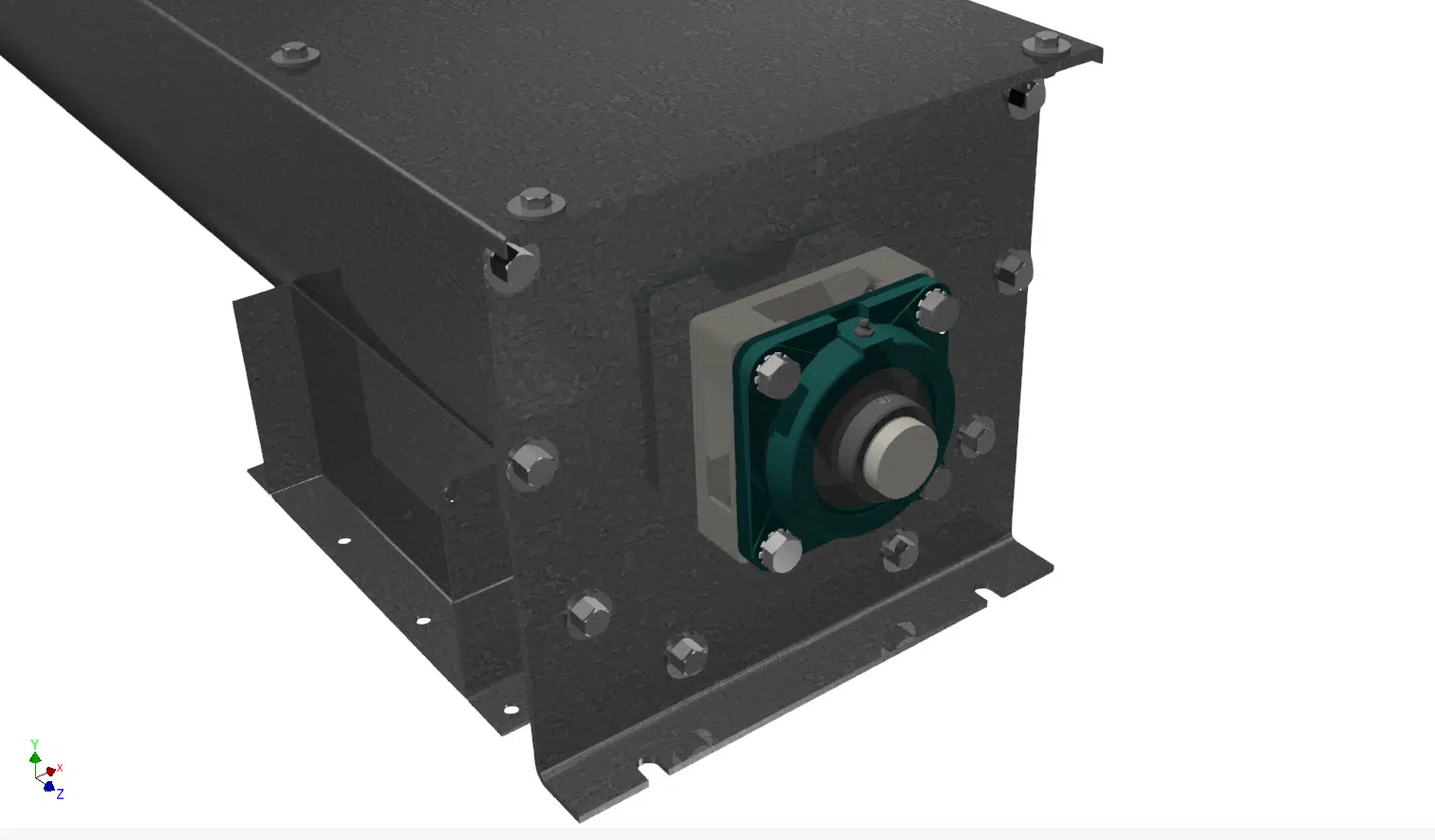

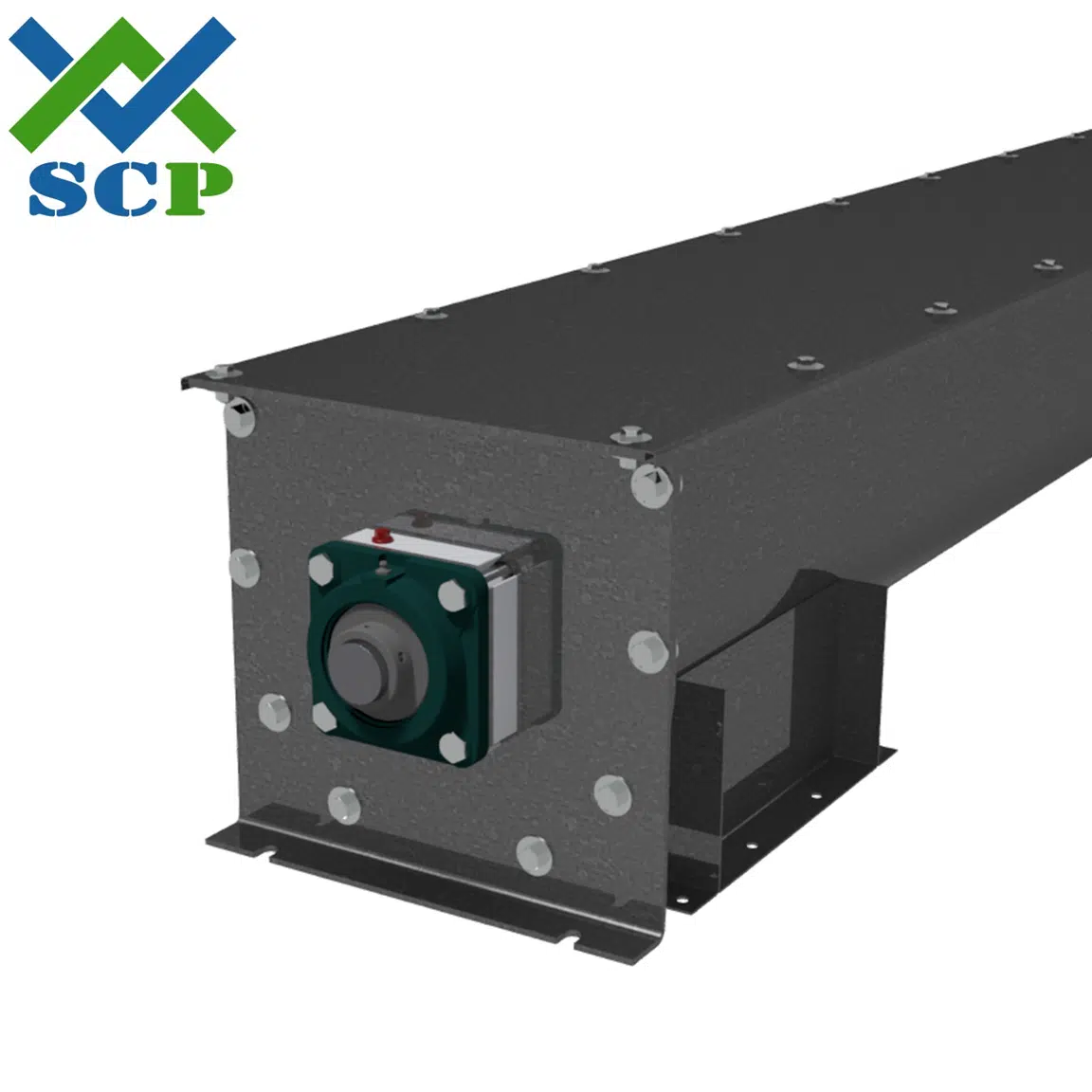

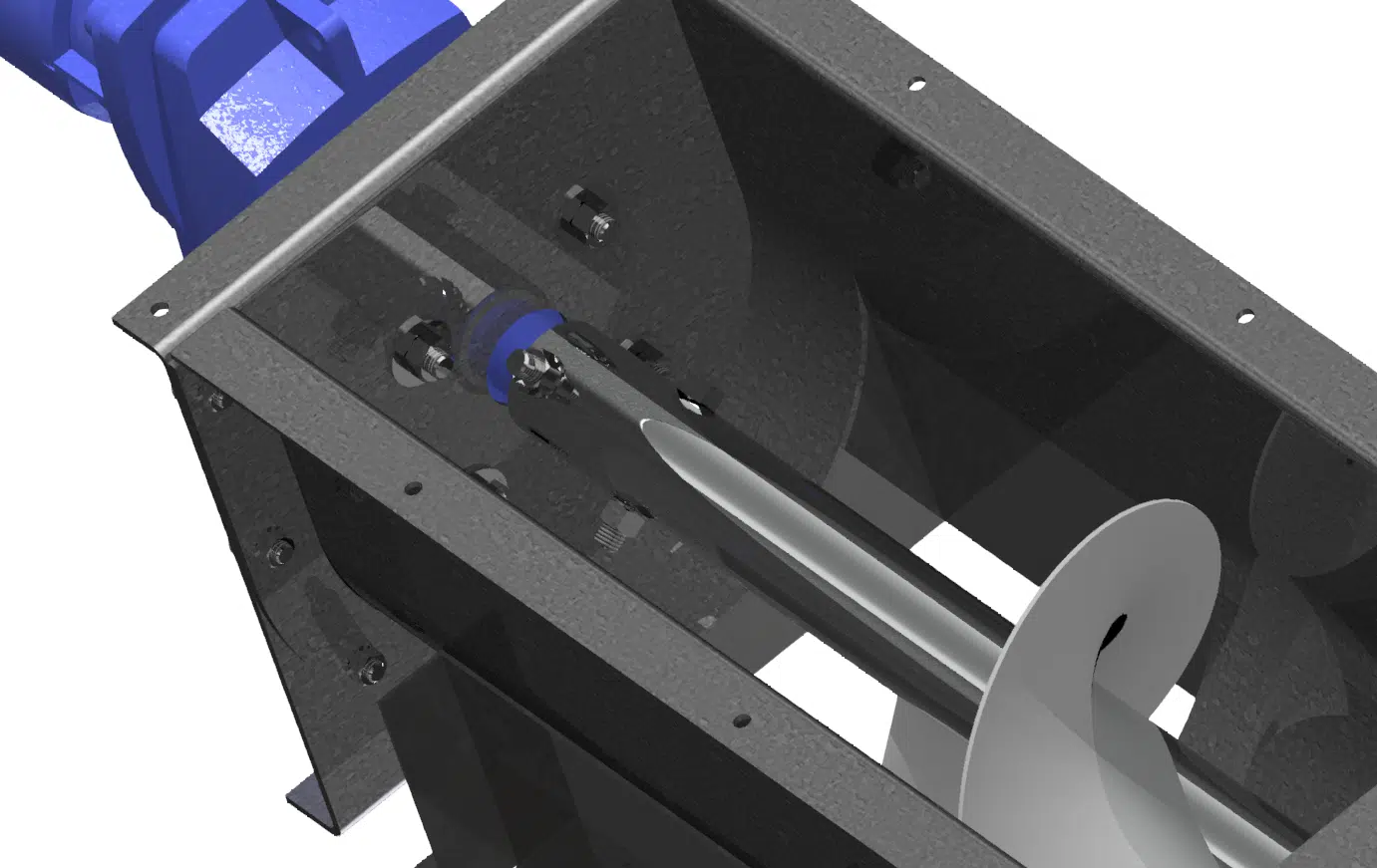

View ProductsTrough End

The screw conveyor trough end serves as an enclosure, conveyor support, screw support. The trough end attaches to both ends of the screw conveyor, at the top is flanged to support the cover, at the bottom acts as a foot to support the conveyor and in the middle has standard bolting for screw conveyor drives, end bearings and shaft seals. SCP offers trough ends for every screw conveyor size and in a few different configurations depending on the bearing or drive being used.

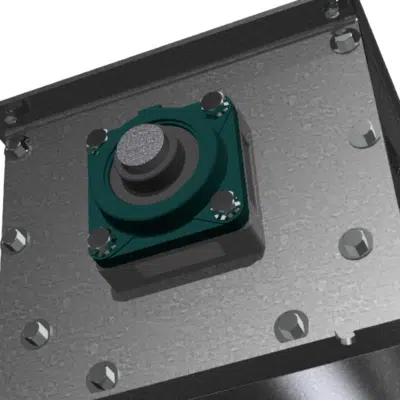

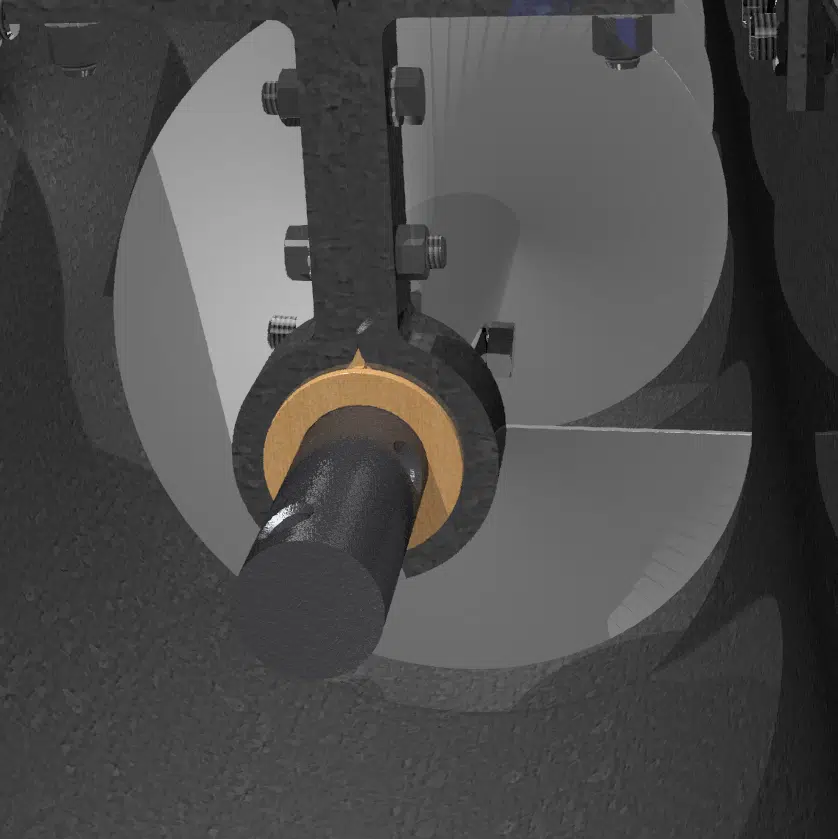

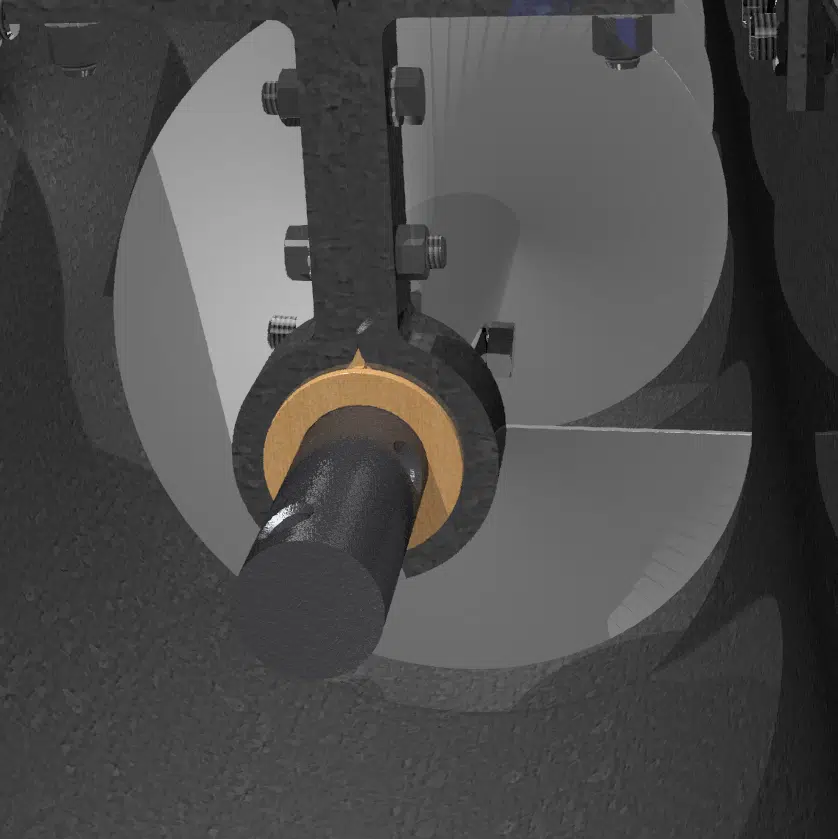

View ProductsShaft Seal

Screw conveyor shaft seals are used to prevent material leakage at the shaft penetration of the drive or tail shaft through the trough end. Often overlooked until there is a problem, shaft seals are available in a wide variety of configurations from the simple plate seal to more complex mechanical seals like the SCP Master Seal. SCP offers the most common shaft seals for screw conveyors for all the standard shaft sizes.

View ProductsShaft Bearing

Screw conveyor bearings are used to support the drive and tail end of the screw. The screw covneyor drive typically has the drive end bearign built in. Good practice is to use a ball bearing at the tail end of the screw conveyor to allow for any runout or misalignment of the screw. The flange bearing is the most common and cost effective. SCP offers bearings for both the drive and tail ends in all the standard shaft sizes.

View ProductsTail Shaft

The screw conveyor tail shaft is used to support the non-drive end of the screw, also called the tail. The tail shaft has botling to match the screw and is long enough to extend fromt he screw, through the trough end, through the shaft seal and to the ball bearing. SCP offers tail shafts in all the standard shaft sizes.

View ProductsInlet

The screw conveyor inlet is pre-sized to maximize the cross-sectional area of the product feed. The inlet is standardized based on the screw diameter and matches the discharge pattern to allow bolting of consecutive screw conveyors together. SCP offers standard inlets for every screw conveyor diameter and a convenient cover with an inlet already mounted for easy assembly.

View ProductsCover

The screw conveyor cover is one of the most important and sometimes overlooked features. The cover serves as an enclosure to elminate dusting, wheather intrusion and most importantly as a safety barrier to protect operators and manitenance personnel. The cover comes in standard 10ft lengths for 6in and 9in conveyors and 12ft lengths for convers 12in and above and can be easly cut to length in the field. SCP offers covers for every screw conveyor size.

View ProductsCover Bolting

Screw conveyor covers can be held to the trough with several different fastener options. The most reliable way is with bolts, although some facilities use screw clamps. Bolts offer the most protection for operators and maintenance personnel since they will not vibrate loose and require a tool to loosen and remove the cover. Most bolts are drilled on either 12in or 24in centers along both sides of the cover the full length. The spacing can be modified to fit specific needs. SCP offers pre-packaged bolting kits for screw covneyor covers for both 10ft (6in and 9in) and 12ft (12in and up) covers.

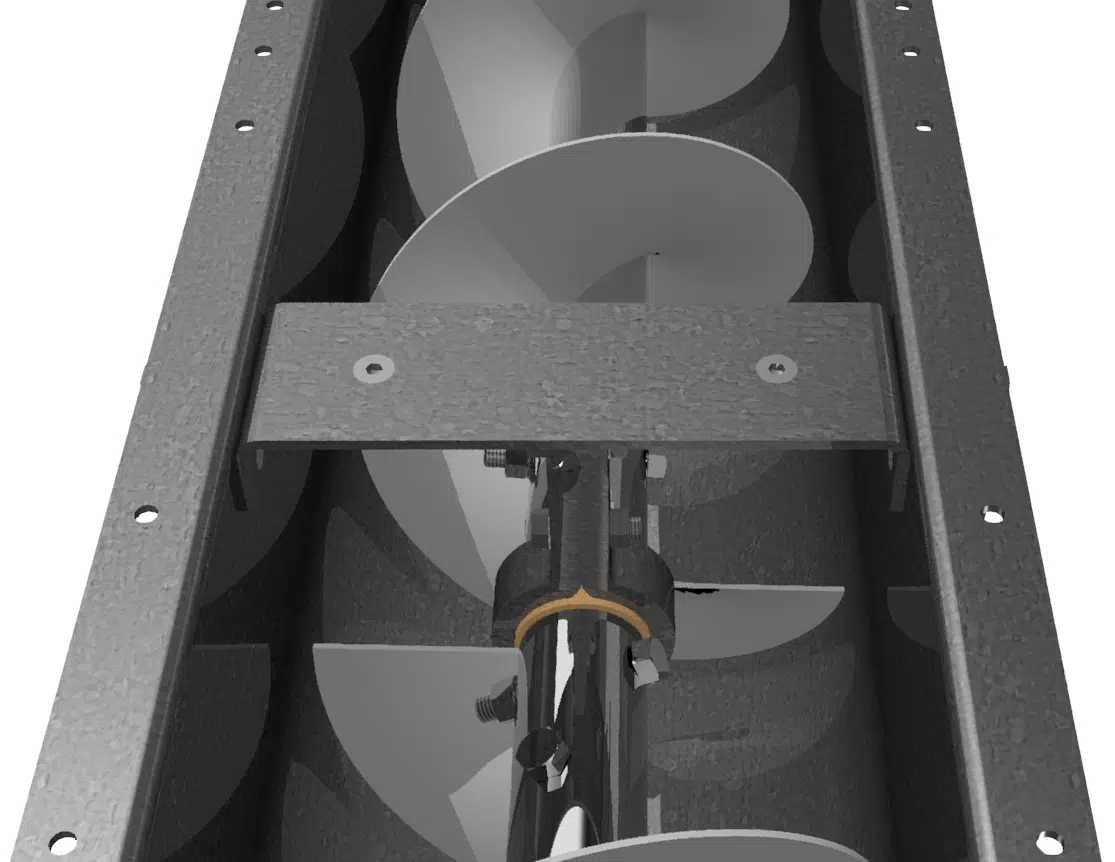

View ProductsHanger Bearing

Screw conveyor hanger bearings are friction bearings used to support long spans of screws. Hanger bearings are available in a wide range of materials and several configurations. The most widely used are style 226, sometimes called 220, with material of construction in Wood, UHMW, and Hard Iron. Hanger bearings require lower through loading to ensure product flows under the hanger bearing and not into it. These are a must part of any spare parts list. SCP offers both 216 and 226 style hanger bearings in a wide veriety of materials.

View ProductsHanger

Screw conveyor hangers are used to support the screw and allow for longer screw conveyors than could be accomplished with a 1-piece screw. The hanger is available in two primary configuration, 216 and 226. The most popular style is the 226. The hanger is specific to each screw and shaft diameter. SCP offers every style of hanger for all the standrd screw conveyor diameters and shaft sizes.

View ProductsCoupling Shaft

Screw conveyor coupling shafts are used to link multiple screw together at each hanger to extend the length of the screw conveyor beyond what can be accomplished with a 1-piece screw. There are multiple types of coupling shafts with the most common being full length. SCP offers standard and hardened coupling shafts for every standard screw conveyor shaft sizes.

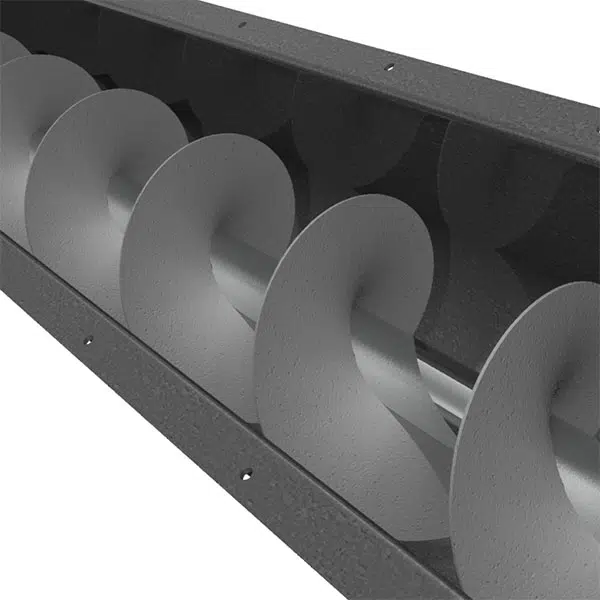

View ProductsScrew

The screw is the heart of the screw conveyor. The screw rotates to provide forward motion to the product being conveyed. Screw are available in a verity of configurations, thickneses, diameters and lengths. Screw flighting can be made of one piece helicoid or segmented with sectional flighting. Helicoid is the most common and cost affective with sectional being requried for any special materials, pitches, thickensse or diameters. SCP offers a wide verity of screws in standard diameters, length and shaft fitment.

View ProductsCoupling Bolt

Screw conveyor coupling bolts are an essential part of the screw conveyor operation. Coupling bolts are specifically desinged to handle the torque output of the screw conveyor drive. Availible in several strengths and specifically built for the shear load between the shaft and the screw these bolts operte in a much more demanding application than other bolts on a screw conveyor. Coupling bolts are usually the torqu limiting item in the screw conveyor which means they are the first to give, protecting much more expensive components. Coupling bolts are a must for any spare parts list. SCP offers coupling bolts for every standard shaft and pipe connection.

View ProductsDrive Bolting

Screw conveyor drive bolting is used to hold the screw conveyor drive to a standard trough end with the use of the screw conveyor adapter. The bolts go through both the trough end and screw conveyor adapter. When properly torqued, these bolts offer abundent clamping force to keep the screw conveyor drive secured. SCP offers drive bolting kits for each size of reducer offered.

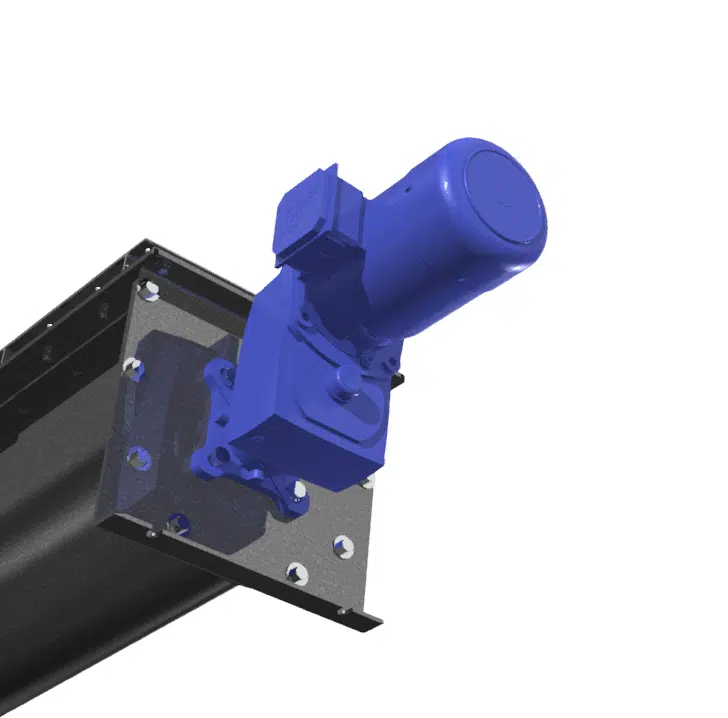

View ProductsScrew Conveyor Drive with Driveshaft

The screw conveyor drive is a motor and reducer configuration with a screw conveyor adapter and driveshaft. Screw conveyor drives bolt directly to the screw conveyor trough end and into the screw. They are used to drive the screw conveyor and are configured to specifically match the HP and RPM requirements of the conveying application. SCP offers several standard drive configurations in the most common HPs and RPMs and can ship in as soon as a 2 weeks.

View Products