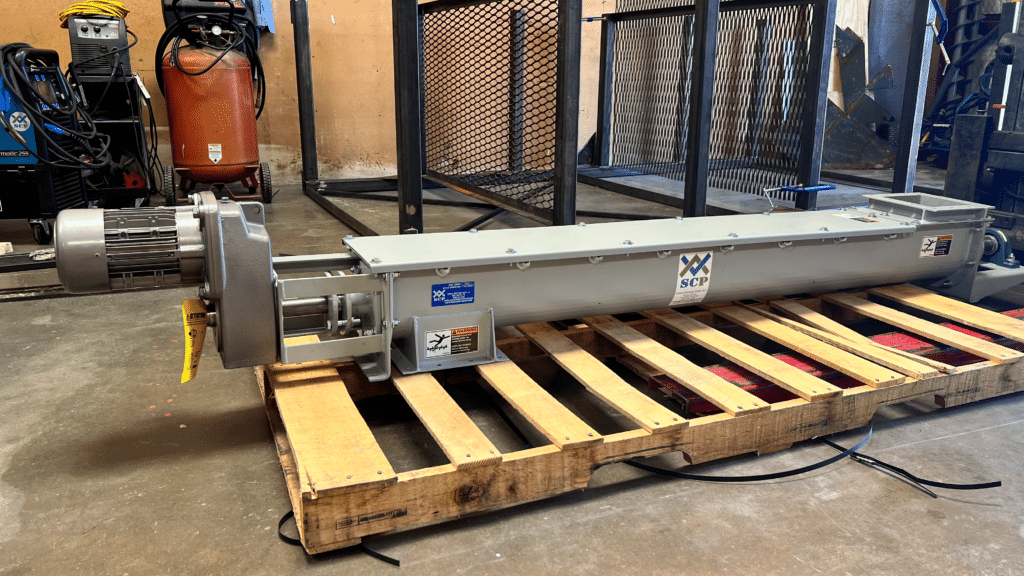

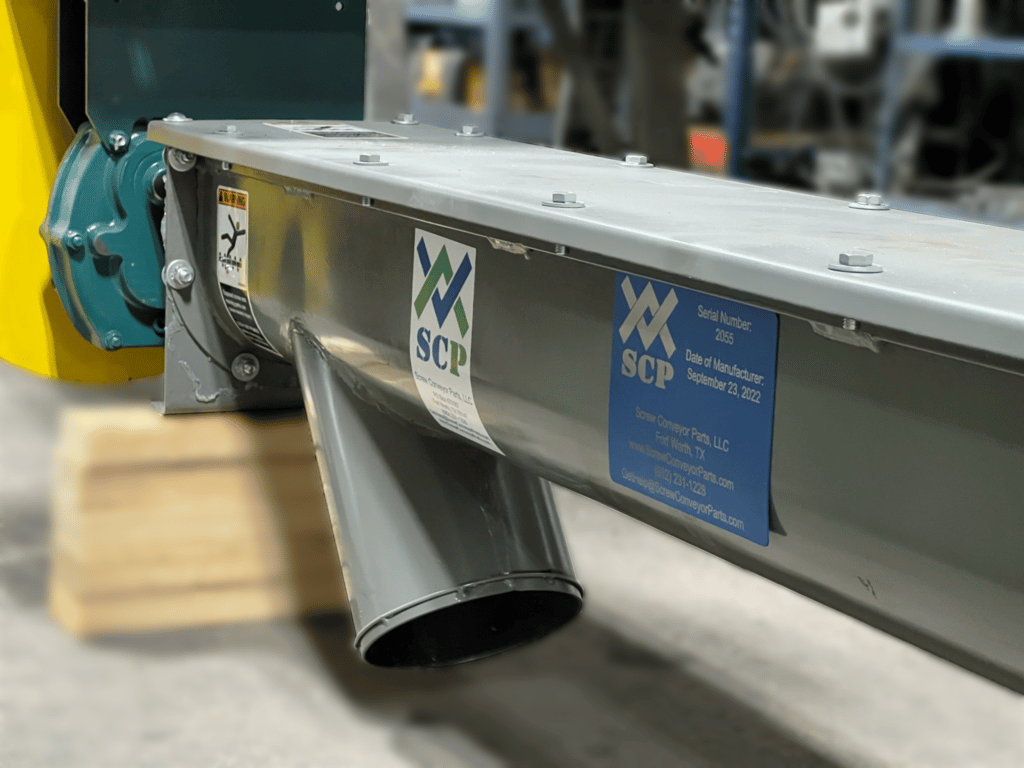

SCP engineers worked closely with the Ardurra engineering team to design the screw conveyors to fit all their needs while keeping cost and delivery as a high priority.

Screw Conveyor Articles

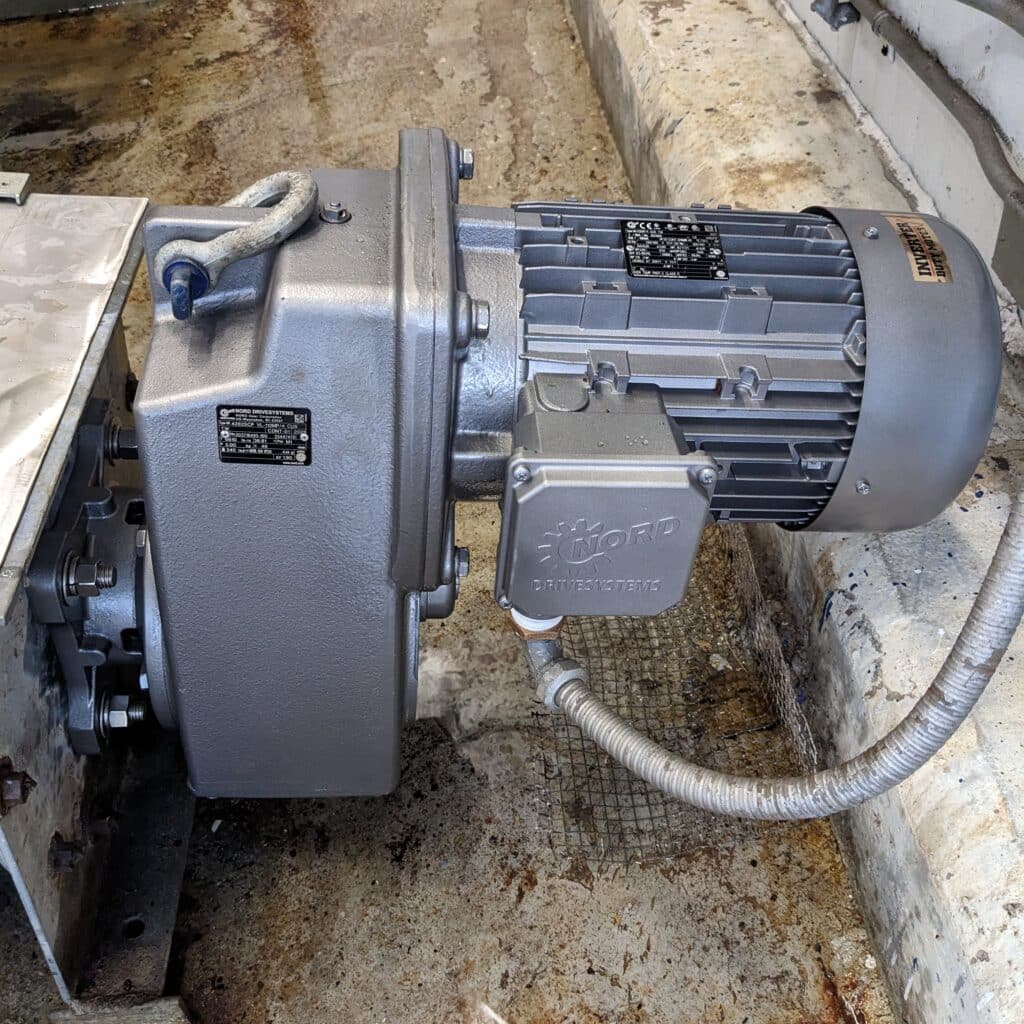

The screw conveyor drive, also called the reducer, refers to the motor/gear reducer assembly used to drive the screw conveyor.

One of the areas we pride ourselves on is designing screw conveyors that both perform well and are economical. How do we do that? We use all stock parts, or modified stock parts. Doing this ensures the cost is kept down, leadtimes are shorter and long term maintenance is easier due to the availability of replacement parts.

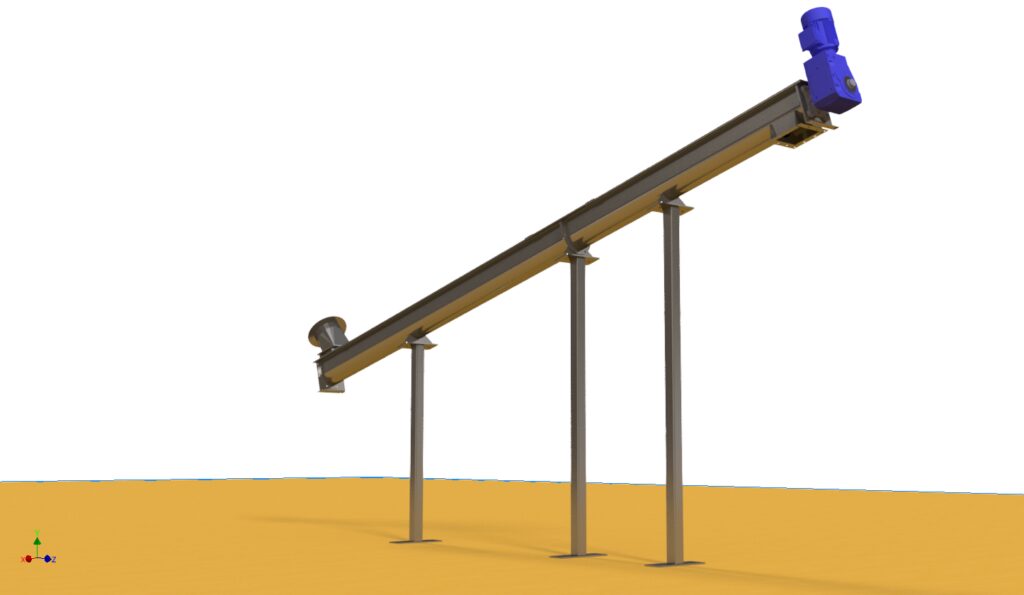

Both screw feeders and incline screw conveyors use shrouds but in different ways.

Screw Conveyor Parts has just released an interactive screw conveyor calculator you can use to size and select your screw conveyor.

Because screw conveyors are standardized among manufactures and most the components are stock, they tend to be the lowest cost equipment for any bulk material process.

SCP engineers worked closely with Wells Ice and Cold Storage to Design a screw conveyor drive that meet all of their needs.

While the majority of screw conveyors are shafted with a spiral wrapped around a center pipe and bushed and drilled at each end for shafts, shaftless screw are a unique product where the center pipe is eliminated and only the spiral is used to convey the bulk material.

Produced Water Solutions (PWS), an industry leader in the treatment of industrial wastewater, had a project in house to treat and dewater wastewater from a domestic industrial producer. The challenge for PWS and where SCP was able to step in was in the conveying of the dewatered sludge after the rotary press.