Screw conveyors are a versatile and economical means of feeding and conveying powder bulk solids in any industrial process. Because of this, screw conveyors have come to be relied on to keep a process flowing. As with any well run industrial process, uptime and reliability are key performance indicators for productivity and directly affect the bottom line. As part of an effective preventative maintenance program having the right spares available at the right time for routine and unexpected repairs is crucial.

At a high level a screw conveyor is a simple machine utilizing a gearmotor, screw and housing, but having the correct spare parts on hand when they are needed can be more complicated due to the endless combinations of variables that go into a screw conveyor design and build. Take a simple screw for example, there are 5 different primary variables (diameter, length, pitch, pipe size, and shaft size) and as many as 10 more when you factor in the secondary variables (pipe schedule, shaft bolting, flight thickness, welding type, etc…). Flight type alone has more than 10 variables (solid, ribbon, cut, saw tooth, tapered, mass flow, etc…). With so many factors it is not reasonable to just wait for your screw conveyor to break and try and order a new part. Below are some considerations and a brief list of the common spare parts for a screw conveyor.

First, lets prevent the failure

Having a regular inspection plan for your screw conveyors is the most important step to eliminating downtime. Inspecting the major components of a screw conveyor both quantitively and qualitatively will allow you to predict failures before they happen. For example, if you have a hanger bearing in cement then you know it is going to wear and eventually fail. A regular inspection and measurement of the wear makes it easy to determine how many hours of runtime you can get out of a hanger bearing before it needs to be replaced. The frequency of inspections is dependent on several factors including how abrasive and dusty the product is, how much the screw conveyor runs and of course how critical it is to the operation.

Common Inspection Points for a Screw Conveyor

– Hanger bearing wear (Check for clearance to the coupling shaft)

– Screw flight wear (Monitor and track thickness)

– Drive, tail and coupling shaft wear (Measure and track diameter)

– Shaft seal wear (Check for leakage)

– Gear Reducer (Check/change oil)

– End Bearings (Check/add grease)

– Build up (Check for build up on the screw and trough)

– Trough wear (Check for thin spots and holes)

Second, what is the cost of your downtime?

The screw conveyor spare parts list if as much dependent on the cost of your downtime as on anything else. For example, if you have a critical screw feeder feeding silica out of a silo for a glass making process and when it shuts down so to does the entire plant, the cost of having an entire $20,000 spare feeder might be worth it. Having an entire spare feeder ensures you have the spares you need and in some cases it might be faster to just swap out the entire screw feeder. In most cases, having a spare feeder is not necessary and following list will provide some guidance. Of course, SCP can supply all the spares you need to keep your screw conveyor up and running.

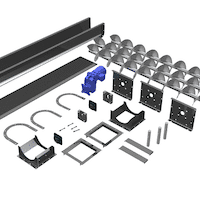

Common Screw Conveyor Spares

– Hanger Bearings

– Coupling Shafts

– Coupling bolts

– End Bearing

– Drive and Tail Shaft

– Shaft seal packing or sealing element

– Cover and flange gasketing

– Gear Reducer