Basic Types of Screws

Stock – Standard – Full Pitch – The vast majority of screw conveyor screws built are standard length, full pitch with skip welded flighting with 2-bolt shafting and are stocked by many screw conveyor manufacturers across the country. Standard nominal length for a screw up to 9″ dia is 10ft and 12ft for 12″ dia and up.

Variable Pitch – Feeder Screws – Variable pitch screws are screws that have more than one pitch along the length. Usually, this is because the inlet is flooded and a short pitch is used to meter the bulk material and then a larger pitch is used to convey the bulk material along the length of the screw conveyor.

Mass Flow Screws – Cone Screws – Mass flow screws use a tapered cone on the pipe through the inlet to meter the flow of bulk material out of a silo, bin or hopper. The cone ensures an even discharge along the entire length of the inlet.

Tapered Screw – A tapered screw has a tapered outside diameter flighting. Like the mass flow screw, the taper ensures an even discharge along the entire length of the inlet.

Terminology

Screw – Auger – Spiral – This refers to the screw which is used to convey the product.

Diameter – This refers to the outside diameter of the flighting of the screw. Screw conveyors are designated by the diameter of the screw. A 9″ screw conveyor has a screw with a 9″ outside diameter.

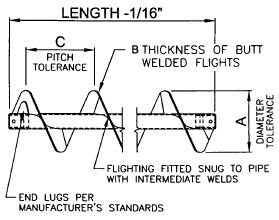

Length – For a screw conveyor, the length is the inside of one trough end to the inside of the other trough end. The screw is offset from this length by a few inches to account for hanger bearings.

Pitch – Full, Half, Two-Thirds, Short, Long – The pitch is the length from one flight to the next. Full pitch means the pitch is the same as the screw diameter; ex: 9″ dia has 9″ pitch. Short pitch can mean anything less than full or some people mean half pitch. Half pitch is a pitch half the screw diameter; ex: 4.5″ pitch for a 9″ dia screw. Long pitch is more than full pitch, usually 1.5x the screw diameter.

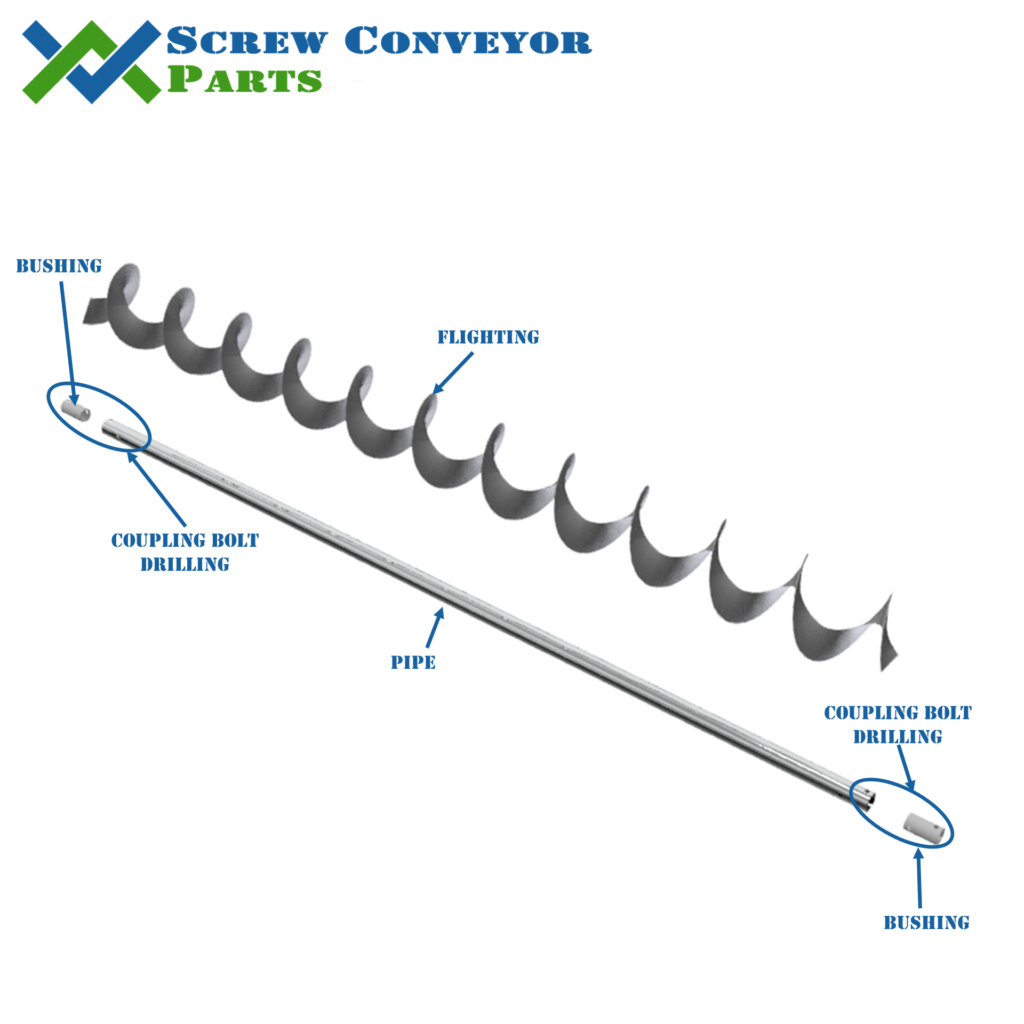

Bolting – 2-Bolt, 3-Bolt – Bolting refers to the number of coupling bolts which connect the drive, coupling and tail shafts to the screw. 2-Bolt offset a specific distance and clocked 90deg is the standard.

Bushing – Internal Collar – The bushing is on the inside of the screw pipe and is used to fill the gap between the screw pipe inside diameter and the drive, coupling and tail shaft outside diameter.

Sectional Flight – A sectional flight is made one pitch at a time on a special press.

Helicoid Flight – A machine uses dies to form a helix to both outside diameter and pitch from a coil steel.

Shaft – Saft referrers to the drive, coupling or tail shaft of a screw conveyor and is used to support the screw.

Pipe – The pipe is the center member the flighting is attached to.

Welding – Skip, Continuous Carrying Side, Continuous Both Sides – When we talk about welding of a screw we are talking about the welding of the flighting to the pipe. Industry standard is skip welded flighting, which usually means alternating welds about 2″-4″ long on both sides of the flighting ever other pitch. Some applications require the flighting to be welded continuously on the front, or carrying, side of the flighting or to be continuously welded to both sides of the flighting.

Cut Flight – Cut flight is a type of screw flighting where the outside diameter of the flighting has rectangular notches cut to allow for gently mixing or breaking up of the bulk material while being conveyed.

Cut and Fold Flighting – Cut and fold flight is a type of screw flighting where the outside diameter of the flighting has rectangular notches cut and then formed at 90deg to allow for gently mixing and tumbling of the bulk material while being conveyed.

Ribbon Flighting – Ribbon flighting is a type of screw flighting where most the inside of the flight has been cut away to form a continuous ribbon along the outside diameter of the screw. Ribbon flighting is used to minimize the corner between the flighting and pipe where sticky materials can build up and to allow for gently mixing.

Flight Edging – Flight edging when the outside diameter of the screw flighting is wrapped with a metal or plastic material to help take up the gap between the screw and the trough or as a surface for the screw to ride on. UHMW flight edging is popular when conveyor fruit.

Hand – Right, Left – The had of the screw refers to the direction the flighting is rotating. Most screws are right hand. If you stand beside the screw and can put your right hand on the flight it is right-handed. The same is true for left-handed flighting.

Double Flighted, Triple Flighted – Double and triple flighting refer to the number of helix wrapped around the center pipe.

Bolt pad – Bolt pads are reinforcements added on the OD of the pipe at the coupling bolt holes to add additional reinforcement to the pipe. Bolt pads add additional bearing capacity to the coupling bolts.

End lugs – End lugs are triangular shaped gussets welded to the end of the flighting to reinforce the flighting connection to the pipe.

Quick Key, Quick Disconnect – Quick Keys are specialty made connections between the pipe and the shafts that allow the screw to be removed without removing the shafts. This is done by notching the pipe at the coupling connection.

Hard Surfacing – Hard surfacing is the application of a hard weld material to the tip, edge or face of a screw. This gives the screw longer life in abrasive applications.