There are a lot of options for screw conveyor shaft seals and choosing the right one for your application can be hard. Below are a few of the most popular options and an explanation of each but first lets talk about what a shaft seal does.

A screw conveyor shaft seal is used to seal the shaft penetration through the trough ends. Without the shaft seal the bulk material being conveyed or fed will come out of the screw conveyor. In most cases the shaft seal on a screw conveyor has an easy job. (Diagram of inlet/discharge) At the inlet the screw pulls the bulk material away from the trough end and at the discharge the bulk material drops out before hitting the trough end. The shaft seal is challenged in applications where the inlet is flooded like in a screw feeder or where the screw conveyor is on an incline and material will be pulled towards the trough end. (Diagram of feeder inlet) Caustic materials, corrosive or any other bulk materials which pose a danger to the environment or health and safety are also examples of instances where the proper selection of the screw conveyor shaft seal is important.

$ – Indicates the relative cost

# – Indicates the relative effectiveness

Good Shaft Seals

These screw conveyor shaft seals are common for horizontal screw conveyor applications where the shaft seal is not flooded

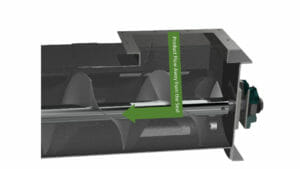

Plate Seal ($,#) – A plate seal is an oil seal pressed into a steal housing. The seal is sandwiched between the trough end and the flange bearing or screw conveyor drive. The screw conveyor plate seal is ideal for bulk materials uniform in size and shape, larger than 1/8″ and non-abrasive. Common bulk materials for a plate seal are whole grain and plastic pellets

Waste Pack Seal ($+,#+) – A waste pack seal is a plate seal with a housing for a fibrous packing. The fibrous packing catches the bulk material as it leaks past the oil seal. Overtime the bulk material in the packing forms a secondary seal. The screw conveyor waste pack seal ideal for bulk materials down to 1/64″ and OK for dusty materials and light abrasives. Common bulk materials for the waste pack seal include corn meal, chemical powders and salt. The waste pack seal is not a good sealing solution for a screw feeder or a screw conveyor on an incline.

Better Shaft Seals

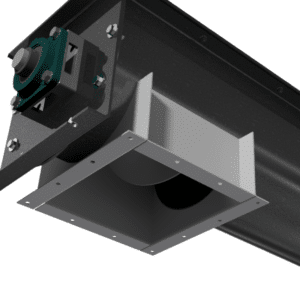

These screw conveyor or screw feeder shaft seals are effective for a wide range of materials and applications. Note that each of these sealing options require the use of a bearing pedestal and pedestal bearing, which are major drivers for the additional costs of each of these sealing options.

Split Gland Seal ($$+,##) – A split gland seal is a compression type seal with a single row of rope packing and a compression sleeve. The compression sleeve squeezes the rope packing against the shaft to create an effective seal. This seal is adjustable and serviceable. The screw conveyor split gland seal works well for all particles sizes down to the smallest powders. The split gland seal works well with abrasive products, too. Common bulk materials for the split gland seal include limestone, chemical powders and dust from a dust collector.

Flange Gland Seal ($$$, ###) – A flange gland seal is also called a packing gland seal or a pump seal. A flanged gland seal is a compression type seal with three rows of rope packing and a compression sleeve. The compression sleeve squeezes the rope packing against the shaft to create an effective seal. This seal is adjustable and serviceable. In many ways it is like the split gland seal, except 3x more effective because of the three rows of packing. The flange gland seal can be designed hold pressure up to about 5psi The screw conveyor flange gland seal works well with particles sizes down to the smallest powders.

Best Shaft Seal

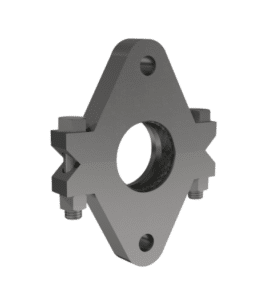

These screw conveyor or screw feeder shaft seals work very well across a wide range of applications and bulk materials. These shaft seal options are recommended with a pedestal trough end for serviceability, but can be retrofitted to screw conveyors with flange bearings where a waste pack seal was being used.

Mechanical Seal