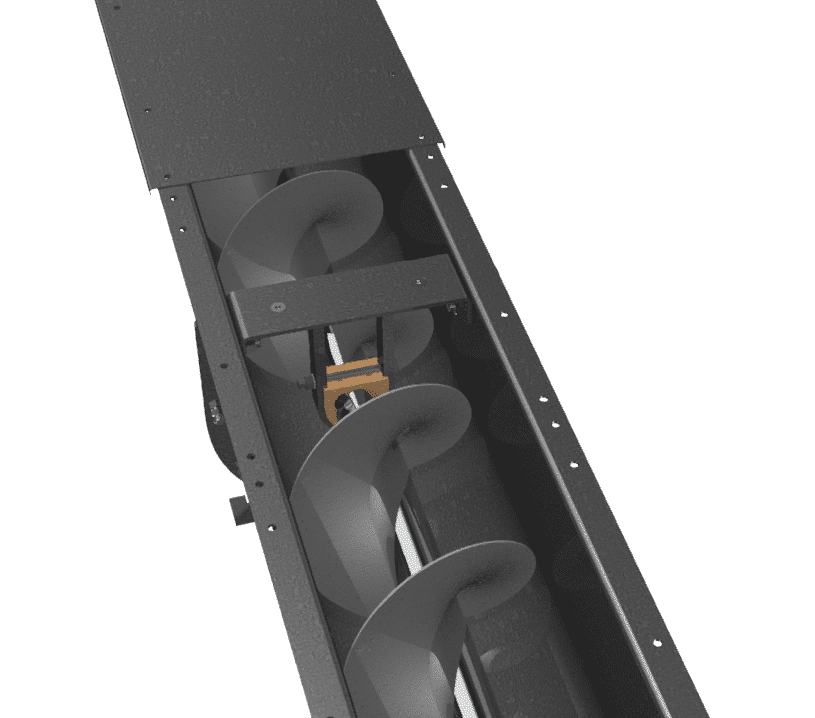

One question we are asked a lot is why is there so much clearance (0.5in) between the screw and the trough (housing)? Like most answers this one is more complex than it seems. The simple answer is the clearance is there to make assembly easier and you would be correct. Oh wait, that was an easy answer.

Let’s dive in to this one a little more. There are two clearances to consider in a screw conveyor. The first is the clearance between the screw outside diameter and the trough inside diameter. This clearance is enough to allow the parts to be manufactured using conventional tooling (not CNC).

Let’s take a 12″ screw conveyor for instance. The outside diameter of the screw is 12in. One must not forget about tolerance in the conventional manufacturing (not CNC) process. Using manual flight presses the tolerances are very large. For example, a 1/4in thk 12in screw has a tolerance of +5/16in and -1/8in. With this tolerance, rework is kept to a minimum and the process is very efficient meaning the parts are very economical. This 204lb screw only cost about $560. About $2.75 per pound. That is not bad considering it has been handled no less than 20 times during the manufacturing process.

The trough also has a manufacturing tolerance to consider. Looking at the same 12″ dia trough x 1/4in thk the tolerance is +1/8in and -1/8in. With these tolerances combined the minimum clearance between the screw outside diameter and the trough inside diameter is 1/2in – 5/16in – 1/8in = 1/16in. Considering the CEMA allowable deflection for the screw of 3/16in (greater than 1/16in) is the reason it is not uncommon to have the occasional slight rub between the screw the trough. This is rare and easily correctable during installation.

The second clearance is between the end of the screw and the inside of the trough. This clearance is quite large (1.5in+) and less to do with manufacturing and more to do with allowing clearance to place an internal thrust washer or shaft seal.

With all the tolerances to consider it is clear why the clearance of 0.5in between the screw and the trough exists. Tightening up the clearance is not uncommon, but does add more labor and $$$ to the cost of the screw