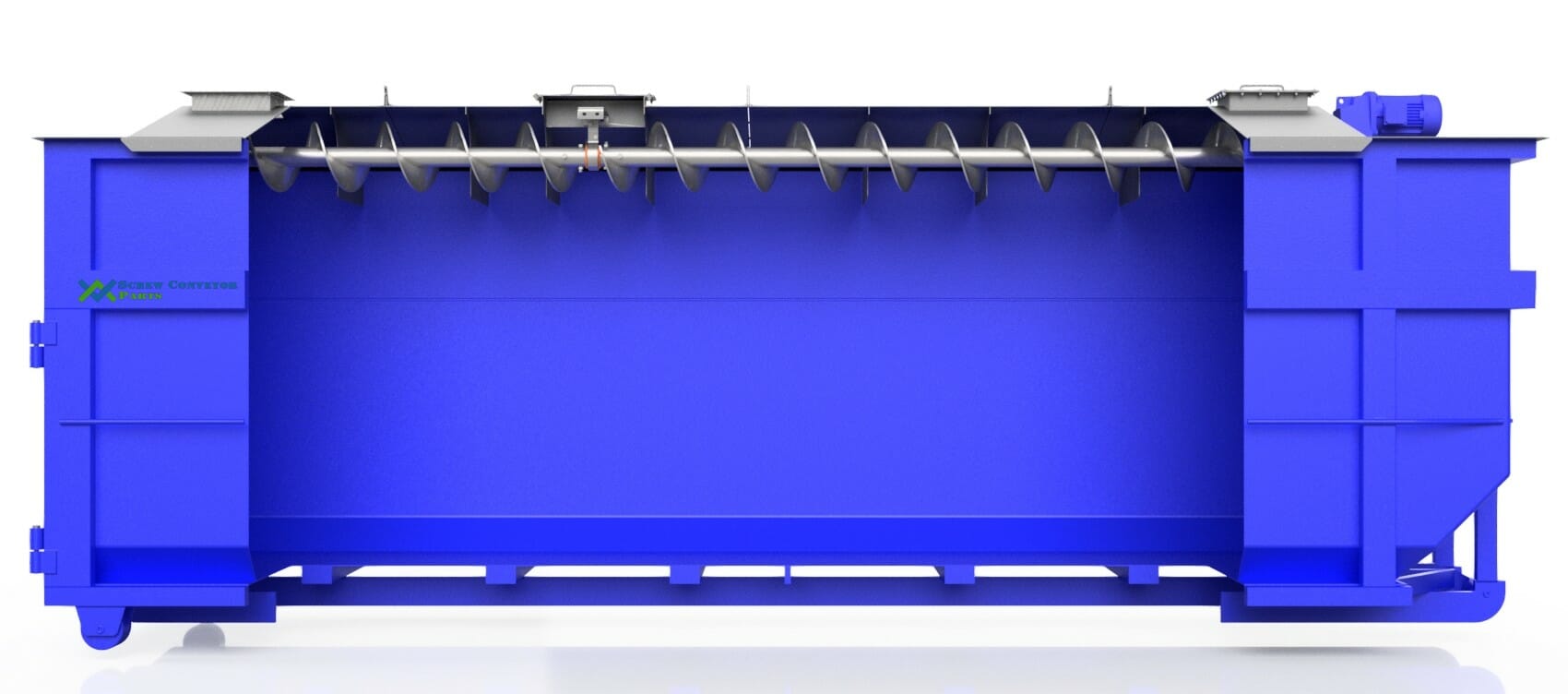

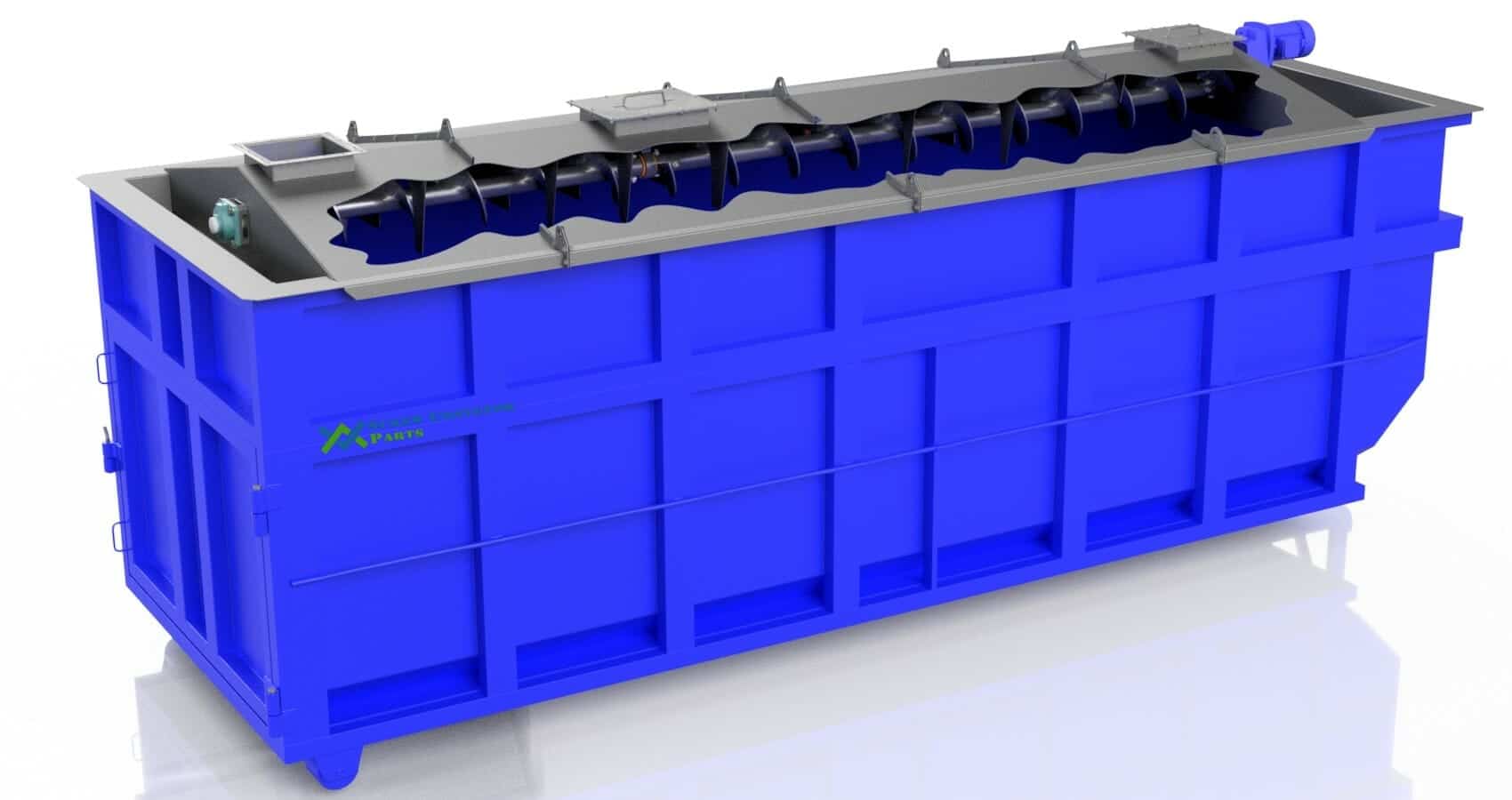

SCP Solution – Dumpster Leveling Screw

Customer:

Gulftech – Casiba; Largo, FL

Application:

Leveling screw conveyor for a dumpster

Equipment:

14in diameter x 22ft long leveling screw conveyor with dumpster cover.

Customer Challenge:

SCP Solution:

Special Features:

– Leveling Screw

– Integral Nord Drive

– Helicoid Flighting

– Self-Supporting Cover

– Dust-Seal Design

– Engineered Screw Conveyor

– 3D Design