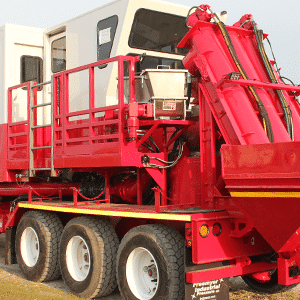

The frac sand blender on the drill site of a modern oil and gas fracking operation is used to blend the proppant with the various chemicals and fluids required to prop open the underground fishers and allow for the extraction of the intended product.

Screw Conveyor Articles

Selecting a screw conveyor screw involves selecting a lot of components and making sure they work well together. The screw is the most critical part of the screw conveyor.

Sizing a screw conveyor can be very easy, when you know a few of the basics. Of course, there are many screw conveyor applications which add elements to the calculation set that require some experience and expertise but for most traditional applications the process is well defined and resources are available in every screw conveyor manufacturer’s catalog.

Feed and Grain is one of the oldest, and most well documented applications for screw conveyors. It is estimated that up to 60% of the total screw conveyor market is in feed and grain and with the explosion in new feed mill builds over the last ten years, this number is growing.

The simple answer is yes, in most cases screw conveyor parts from any manufacturer will fit in your screw conveyor.

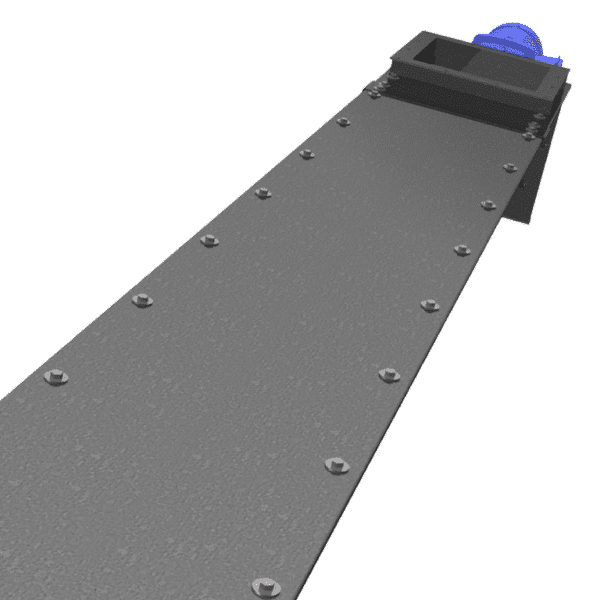

The screw conveyor cover is used to enclose a u-trough, flared or rectangular trough screw conveyor.

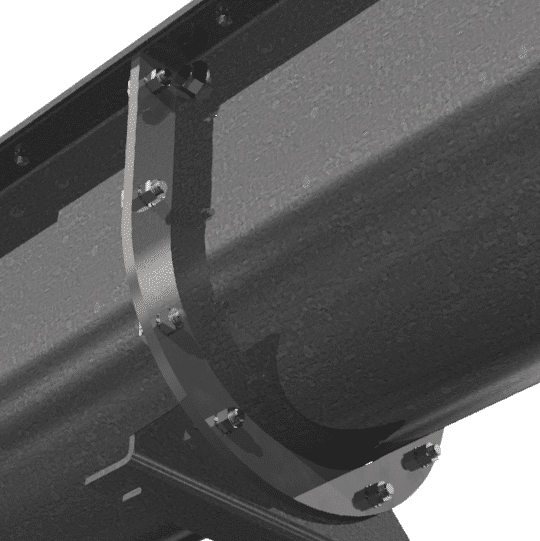

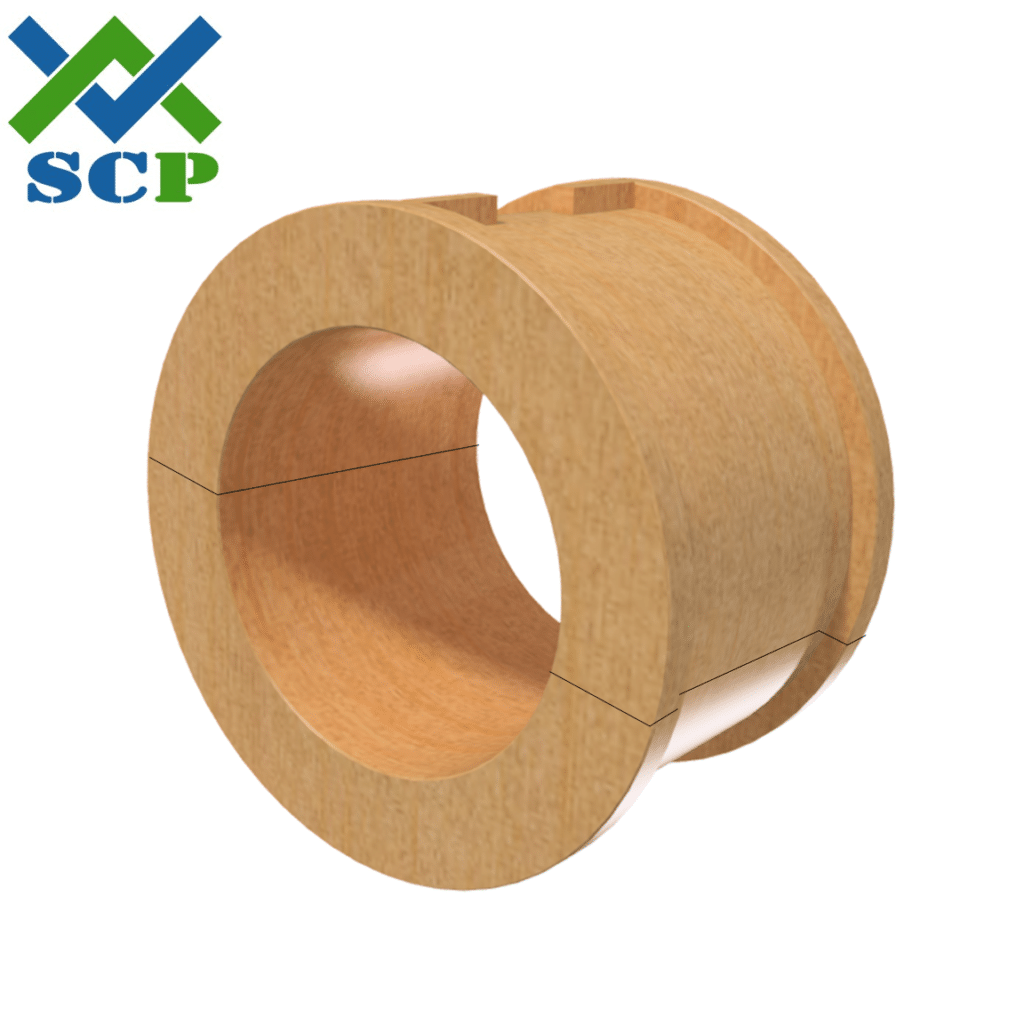

A screw conveyor hanger bearing is commonly used in screw conveyors over about 12-14 feet. It is a friction, also called a plain, bearing used to support the coupling shaft and the ends of multiple screws.

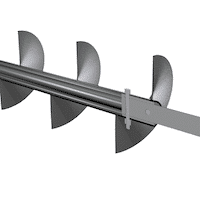

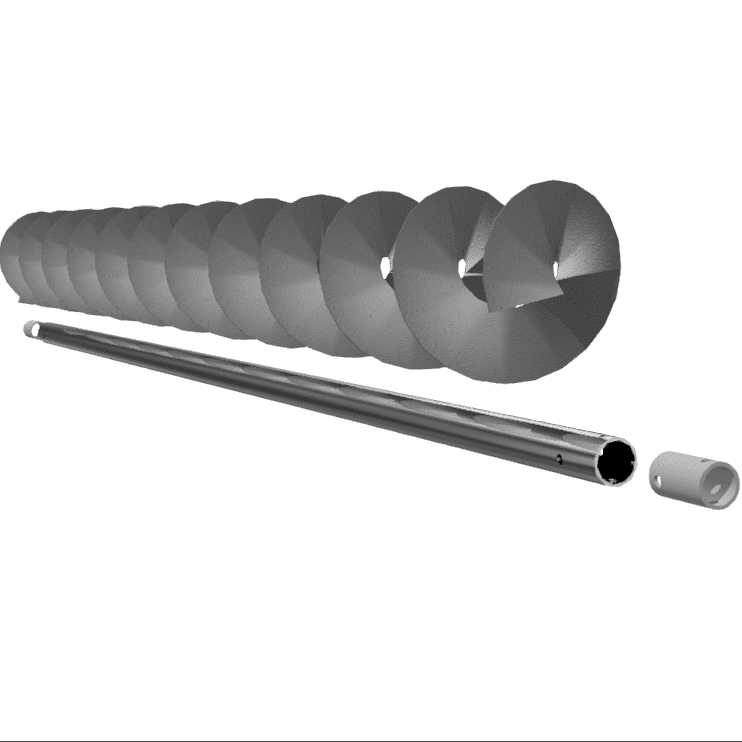

A screw conveyor, also called an auger is a mechanical conveying device for powder bulk solids. At the heart of the screw conveyor is the screw.

A screw, or sometimes called an auger is the heart of the screw conveyor. The screw is rotated by the screw conveyor drive and pushes the conveyed material forward 1 pitch with every revolution.