“Speed kills, abrasion kills and shaft seals are almost useless”

These 3 things to remember when designing a screw conveyor or screw feeder. If you want a screw conveyor that will last forever keep these words in mind.

#1 – Slow the conveyor down. Standard published speeds are way too fast for any application outside of a feed mill. Grain is a the most idealistic example of a free-flowing powder bulk material. For all chemicals, most plastics, sand and almost all other industrial products run the screw conveyor at 30 – 60 rpm and 20-40 rpm for a screw feeder.

#2 – Abrasion kills. – Slowing down the screw conveyor is a good start to fight abrasion. The second is to use a thicker flighting and/or abrasion resistant material. Click HERE to learn more about fighting abrasion.

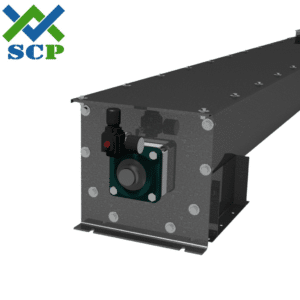

#3 – Shaft seals are almost useless…….in most incline, feeder and abrasive applications. The standard low-cost shaft seal such as a waste pack seal works well if the conveyor is horizontal or the product being conveyed is granular and non-abrasive. Better seal alternative are seals that utilize a pillowblock bearing like a split gland and packing gland or a mechanical seal such as an air purge SCP Master Seal. Click HERE to learn more about shaft seals.