Conveying salt in a screw conveyor is a very common application. Screw conveyors are well suited for the salt industry because they are sealed to keep contaminants out, product in and heat and steam contained. Screw conveyors can be custom configured to fit a wide variety of salt conveying applications, flow rates, configurations and features to perfectly match your conveying needs. This article discusses a few points to consider when selecting a screw conveyor for salt, including material of construction, hanger bearing selection, cover design and seal design.

Material of Construction

As many people working in the salt industry know and many living near an ocean, salt is extremely corrosive to metal, especially when water or steam is added to the equation. When selecting materials of construction for your salt screw conveyor, using uncoated carbon steel will leave you with a pile of rust in just a few months. Some manufacturers have tried spray on coatings for carbon steel, but because of the slightly abrasive nature of salt these coating can quickly wear off and expose the carbon steel below. 304 Stainless steel offer some protection but does not preform much better than carbon steel. For the best, commercially available material of construction, 316 stainless steel is recommended for salt conveying applications. No manufactures stock 316SS screw conveyor components so these screw conveyors are made to order. Click HERE for custom screw conveyor RFQ

Hanger Bearing

Although it is best to design the screw conveyor with as few hanger bearings as possible by lengthening the screws, it is inventible a hanger bearing will be needed. Hanger bearings are a regular maintenance item. Allowing access to them for regular inspection and replacement is a must. If the trough loading is kept low (30% or less) you can expect a reasonably long life out of almost any hanger bearing material. Because most common salts are light in color a hanger bearing of similar shade is typically preferred in case some of the hanger bearing shavings get into the salt. White UHMW is a very popular choice for many salt screw conveyors. UHMW hanger bearings are economical and available for immediate shipment. Click HERE for available hanger bearings

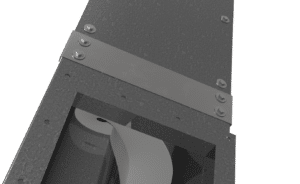

Cover Design

Screw conveyor cover design is one of the most overlooked aspects of a screw conveyor. A standard gasketing and bolting system for covers is barely adequate for low temperature, free flowing materials. When conveying salt coming out of the dryer, with steam and heat being put off, special attention must be paid to the cover system. Tightening up the bolting from 24″ centers to 12″ centers is a good idea, along with looking at a 4-sided bolting arrangement is some added comfort. The gasketing selection must not be overlooked, either. Using something like a silicone gasket able to stand moderate temperatures and moisture is a good choice. It is always a good idea to place a shorter cover section directly over the hanger to allow for easy inspection and replacement. A hinged, grated and clamped cover over the hanger is a nice feature your maintenance personnel will appreciate in areas where the temperature pf the salt is not too hot. Click HERE for available covers and accessories

Shaft Seal

The shaft seals at the ends of the screw conveyor are always an area to pay special attention to for salt. The most common screw conveyor shaft seal is the waste pack seal. It is adequate for dry, horizontal conveyors where the trough loading is kept low. Packing gland seals are recommended for incline applications or where hot salt is being conveyed because of the triple row packing system that offers superior sealing to the single lip seal of the waste pack seal. Just keep in mind the packing gland seal will required a pedestal trough end and a pillowblock bearing. Click HERE for available shaft seals

Still have questions? Email us at [email protected]